In the landscape of modern manufacturing, the foam cutting machine plays a pivotal role. From protecting delicate electronics in the packaging sector to crafting ergonomic seats in the automotive industry, the demand for precise and efficient foam processing is at an all-time high.

As technology evolves, so do the capabilities of these machines. It is no longer just about slicing material; it is about intelligent automation, material optimization, and multi-functional processing. This article delves into the cutting-edge technical features of modern foam cutters, explores their diverse industry applications, and guides you on selecting the right equipment to elevate your business.

1. Technical Features: What Sets Modern Foam Cutters Apart?

To stay competitive, manufacturers need equipment that offers more than just basic functionality. Here are the four key technical advancements defining today's top-tier foam cutting solutions.

1.1 High-Precision Cutting

Precision is the cornerstone of quality. Advanced CNC control systems now allow for cutting tolerances as tight as ±0.1mm. Whether you are working with soft PU sponge or rigid XPS, this level of accuracy ensures that every part fits perfectly, eliminating the need for manual trimming and reducing rejection rates.

1.2 Automation and Intelligence

The era of manual feeding is fading. Modern CNC foam cutters are equipped with:

Automatic Feeding Systems: Allowing for continuous, roll-to-roll processing.

Smart Nesting Software: AI-driven algorithms that arrange patterns to maximize material utilization, significantly reducing waste and raw material costs.

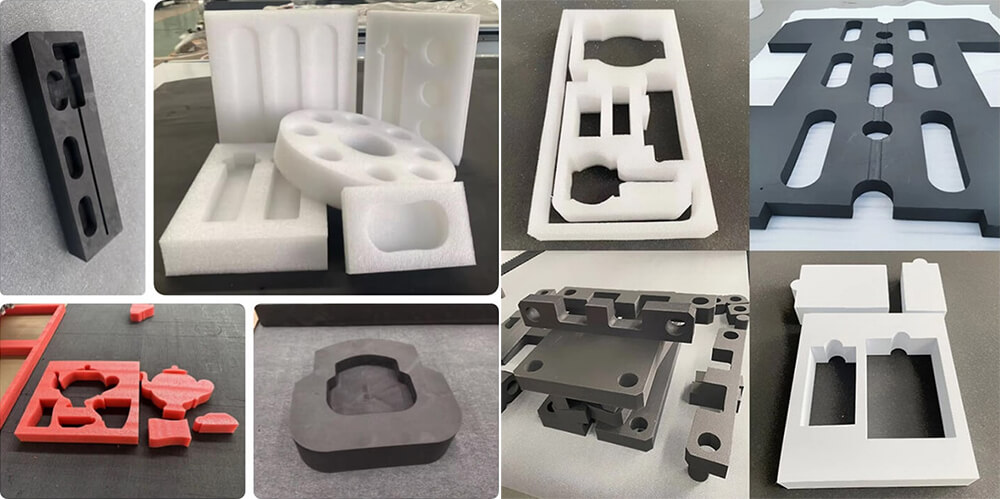

1.3 Versatility: Cutting Meets Milling

One of the most significant innovations is the integration of milling tools. A foam cutting machine with a router can perform standard through-cutting and intricate depth-milling in a single pass. This is ideal for creating complex 3D shapes, pockets for packaging inserts, and detailed prototypes without changing machines.

1.4 Eco-Friendly Design

Sustainability is a priority. Unlike traditional hot-wire cutters that may produce smoke, or saws that create excessive dust, modern oscillating knife cutting technology offers a clean, dust-free solution. This not only creates a healthier work environment but also ensures the final product is clean and ready for immediate use.

![Technical Features & Industry Applications of Foam Cutting Machines: The Ultimate Productivity Booster Technical Features & Industry Applications of Foam Cutting Machines: The Ultimate Productivity Booster]()

2. Industry Applications: Where Efficiency Meets Innovation

The versatility of foam cutting machines allows them to serve a wide array of sectors.

2.1 Packaging Industry

Protective packaging requires exact fits to ensure safety during transit. Foam cutters produce custom EPE and EVA foam inserts that cradle products securely. The ability to rapidly switch designs makes them perfect for both high-volume runs and small-batch custom packaging.

2.2 Furniture Manufacturing

Comfort relies on complex curves. In the furniture industry, machines process PU foam for sofas, mattresses, and chairs. Automated cutters can handle the intricate contours required for ergonomic designs much faster and more consistently than manual labor.

2.3 Construction and Insulation

For energy efficiency, insulation materials like XPS and EPS must be cut precisely to prevent thermal bridging. CNC foam cutters are also widely used in architectural modeling, allowing architects to create detailed 3D scale models directly from CAD data.

2.4 Automotive Manufacturing

From soundproofing mats to gaskets and seat cushions, the automotive sector demands speed and consistency. Die-less cutting systems allow manufacturers to produce foam parts for prototyping and mass production without the high cost and lead time of physical molds.

![foam board cutting machine foam board cutting machine]()

3. How to Choose the Right Foam Cutting Machine

Selecting the right equipment is a strategic investment. Consider these four pillars before making a decision.

3.1 Assess Production Needs

Are you doing rapid prototyping or mass production? High-volume lines benefit from conveyor systems and auto-loading, while prototyping shops might prioritize versatility and software compatibility.

3.2 Consider Material Compatibility

Different foams react differently to cutting methods.

Soft Foams (Sponge, PU): Best suited for Oscillating Knife Cutters.

Rigid Foams (XPS, EPS): May require Hot Wire or Routing tools.

Dense Rubber/Gaskets: Require heavy-duty Pneumatic Oscillating Tools (POT).

3.3 Budget vs. ROI

Look beyond the initial price tag. Calculate the Return on Investment (ROI) by considering material savings (via nesting software), labor reduction (via automation), and the potential for new business (via increased capabilities).

3.4 After-Sales Service and Support

A machine is a long-term partner. Ensure your supplier offers robust technical support, spare parts availability, and comprehensive training to keep your production running smoothly.

4. Customer Success Stories

Case Study: The Custom Packaging Leader

A packaging client specializing in fragile electronics switched from manual die-cutting to our Digital Foam Cutter.

Challenge: High mold costs for small orders and excessive material waste.

Solution: Implemented a cutter with smart nesting.

Result: Material waste reduced by 20%, and they can now offer "same-day sample" services to their clients.

Case Study: The Acoustic Panel Manufacturer

A manufacturer of acoustic foam panels needed cleaner edges for a premium product line.

Solution: Adopted our dust-free oscillating knife technology.

Result: Achieved a perfect finish with zero secondary cleaning required, increasing daily throughput by 35%.

Conclusion

The foam cutting machine is more than just a tool; it is a catalyst for growth. With features like high-precision cutting, intelligent automation, and multi-functional milling, these machines empower businesses to produce higher quality products faster and more sustainably.

By understanding the technical advantages and aligning them with your industry needs, you can make an informed choice that secures your competitive edge.

Ready to upgrade your production capabilities?Contact us today for professional advice, a personalized demo, or a quote. Let us help you find the perfect foam cutting solution for your business.

Frequently Asked Questions (FAQ)

Q: Can a foam cutting machine handle both soft and rigid foams?

A: Yes, many advanced machines are modular. You can swap tool heads (e.g., changing from an electric oscillating knife for soft foam to a routing spindle for rigid foam) to handle different materials on the same machine.

Q: How does the nesting software save money?

A: Nesting software automatically calculates the most efficient layout of parts on a sheet of foam. This minimizes the gaps between parts, significantly reducing scrap waste and lowering your raw material costs.

Q: Is the machine difficult to operate?

A: No. Modern CNC foam cutters come with user-friendly interfaces. If you can use basic CAD software, you can easily learn to operate the machine. We also provide comprehensive training for all our clients.