Perfect Cuts on Soft Foam, Every Time: The SL1625SF Digital Cutter

Cutting sponge and other soft foams presents a unique challenge. Manual cutting is notoriously inaccurate, resulting in angled edges and deformed shapes due to material compression. Traditional die-cutting is expensive, slow to implement for custom jobs, and completely impractical for prototyping or small-batch production. These limitations lead to material waste, inconsistent quality, and slow production cycles.

The SL1625SF Sponge Flatbed Digital Cutter is engineered to master these challenges. It replaces imprecise manual labor and inflexible dies with a highly accurate, fast, and versatile digital workflow. Transform full sheets of sponge and foam into perfectly finished components with unmatched precision and efficiency.

Core Advantages: Engineered for Sponge & Soft Materials

The SL1625SF is designed from the ground up to deliver flawless results on the most challenging soft foams.

1. Zero-Compression Cutting with an Oscillating Knife

This is the key to perfect sponge cutting. Unlike blades that drag or presses that crush, the SL1625SF uses a high-frequency oscillating knife. The blade moves vertically at thousands of strokes per minute, slicing cleanly through the material without compressing or distorting it. The result is perfectly vertical, smooth edges, even on intricate curves and sharp corners.

2. Unwavering Stability with a Regional Vacuum Table

Soft, porous materials are difficult to keep flat and stable during cutting. Our intelligent regional adsorption vacuum table solves this problem. It divides the work table into independent zones, allowing you to concentrate powerful suction exactly where you are cutting. This ensures the sponge is held firmly in place, eliminating material shift and guaranteeing the ±0.1mm accuracy required for high-quality furniture cushions and snug-fitting packaging inserts.

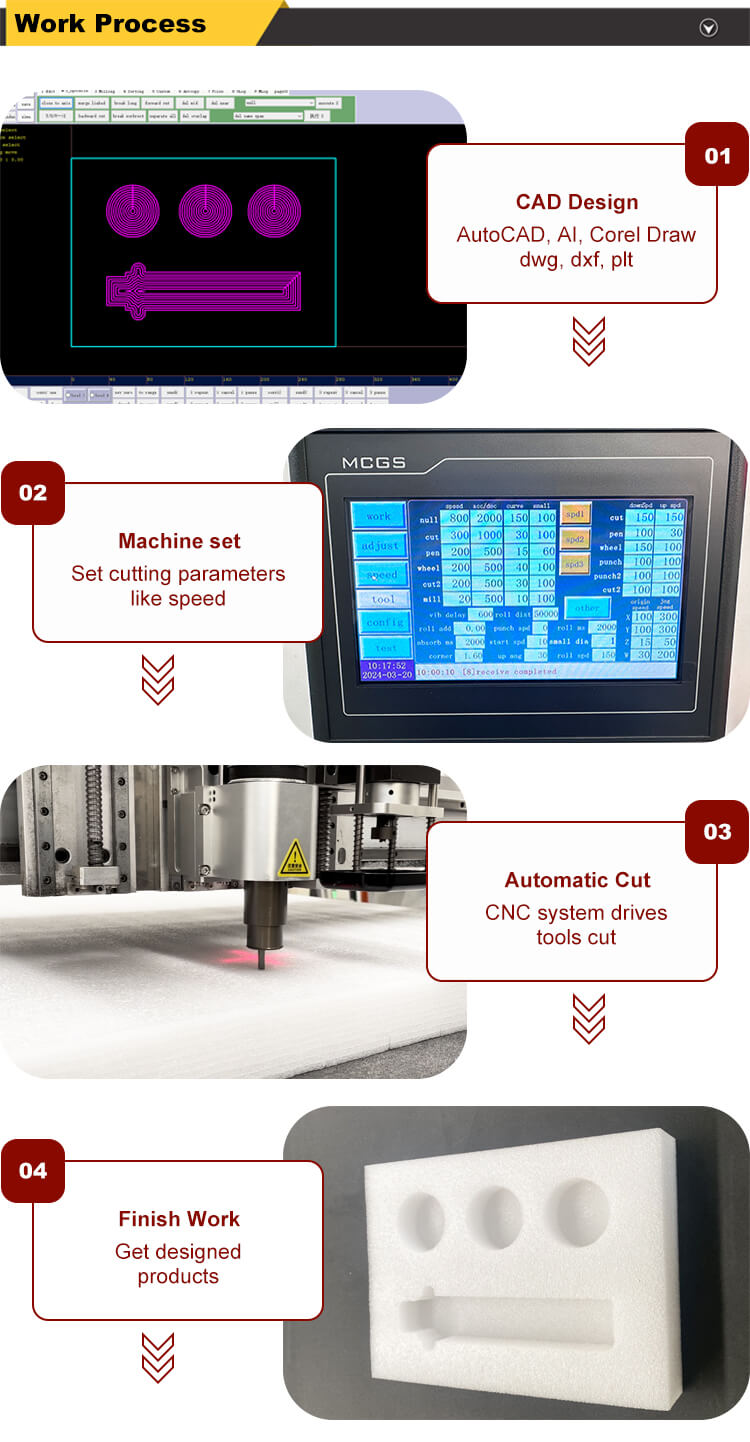

3. From CAD to Cut in Minutes: The Power of Digital & Nesting

Eliminate the cost and lead time of die-making forever. The SL1625SF operates directly from your CAD files (AutoCAD, SolidWorks, etc.). More importantly, the included intelligent nesting software automatically arranges your parts on the material sheet to maximize yield and dramatically reduce waste. Go from a new design to a finished product in minutes, making your operation more agile and profitable.

![foam sheet cutting machine foam sheet cutting machine]()

SL1625SF Technical Specifications

Parameter | Specification |

Model | SL1625SF |

Working Area | 1600mm × 2500mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Work Table | Vacuum Table (Regional Adsorption) |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

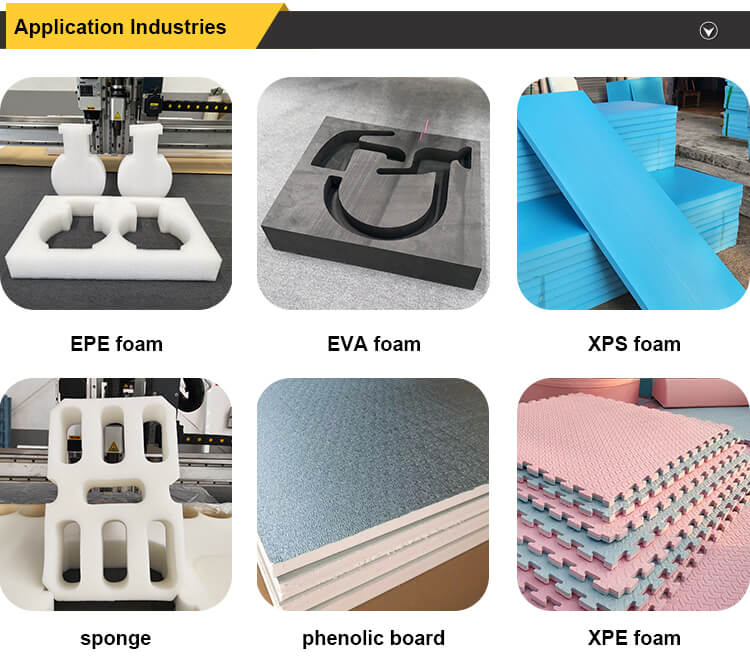

Applicable Materials | Sponge, EPE, EVA, EPS, XPS, PVC, EPDM, XPE Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Gross Weight | 1500kgs |

Warranty | 3 Years |

The Essential Machine for a Range of Industries

The precision and versatility of the SL1625SF make it a cornerstone for businesses that value quality and efficiency.

Furniture & Upholstery: Produce custom sofa cushions, chair pads, mattress toppers, and complex upholstery components with perfect consistency.

Protective Packaging: Fabricate high-performance, precision-cut foam inserts for tool cases, electronics packaging, and medical device transport.

Acoustic Treatment: Cut intricate acoustic panels, bass traps, and sound-dampening components for recording studios, home theaters, and commercial spaces.

Sports & Leisure: Manufacture protective padding for helmets, gymnastic mats, and other sporting goods.

Gaskets & Seals: Cut soft foam gaskets and seals from materials like EPDM and EVA with high precision for industrial applications.

![foam cnc cutter machine foam cnc cutter machine]()

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our team has deep experience in cutting soft and porous materials. We will help you configure the perfect system, including the right blades and vacuum setup, to conquer your specific production challenges.

A Fully Integrated System: You receive a turnkey solution. The machine, nesting software, tools, and regional vacuum system are pre-configured to work together seamlessly, ensuring you are productive from day one.

Global Installation & On-Site Training: Our certified technicians provide professional installation and train your team on machine operation, software, and maintenance, guaranteeing a fast and successful implementation.

Authoritative 3-Year Warranty: We are so confident in the robust construction and reliability of our machines that we back the SL1625SF with an industry-leading 3-year warranty for your peace of mind.

Lifetime Technical Support: Your success is our mission. You gain a dedicated partner with lifetime access to our expert support team for any operational or application questions.

Ready to Master Your Sponge & Foam Cutting?

Leave the inaccuracies of manual cutting and the high costs of die-cutting behind. Embrace the speed, precision, and flexibility of a digital cutting solution.

Contact us today to discuss your application with a soft foam cutting specialist and request a quote and a free material test.

Get a Quote & Free Material Test!