Beyond the Cut: The SL1625FM Foam Cutting & Milling Machine

Simple through-cuts are not enough for today's advanced applications. Creating custom tool inserts, multi-level packaging, and detailed prototypes requires creating pockets, grooves, and chamfered edges. Traditionally, this means cutting the outline on one machine and then moving the part to a separate, manual routing station. This two-stage process is slow, prone to error, and drives up labor costs, compromising both your efficiency and the quality of your final product.

The SL1625FM Foam Cutting & Milling Machine is the integrated solution. It combines two critical fabrication processes—high-frequency knife cutting and high-speed milling—into one powerful, automated workflow. Now you can produce complex, multi-dimensional foam components with unmatched precision and speed, all on a single machine.

Core Advantages: Engineered for Complex Foam Fabrication

The SL1625FM is purpose-built to give you complete control over the geometry of your foam parts.

1. Integrated Cutting & Milling: One Machine, Endless Possibilities

This is the heart of the SL1625FM's power. The dual-tool head allows the machine to intelligently switch between functions in a single program:

Oscillating Knife: Slices cleanly through foam to create precise perimeters and through-cuts without material compression.

High-Speed Milling Tool: Excavates material to create pockets at specific depths, carves grooves and channels, engraves part numbers, and adds chamfered or rounded edges. This single-workflow process eliminates part handling between stages, drastically reducing production time and eliminating alignment errors.

2. Flawless Precision for a Perfect Fit

Whether you're creating a snug pocket for a delicate instrument or a precise groove for a gasket, accuracy is paramount. The SL1625FM is built on a rigid frame and driven by high-performance Japan servo motors to deliver a repeatable cutting tolerance of ±0.1mm. A powerful vacuum pump holds the material firmly to the table, preventing any shifting even during aggressive milling operations, ensuring every feature is exactly where your design intends it to be.

3. Streamlined CAD-to-Part Workflow

Turn your digital designs into physical parts with incredible ease. The SL1625FM works directly with your existing CAD and vector files (SolidWorks, AutoCAD, AI, etc.). Our intuitive software automatically generates the optimal toolpaths for both the cutting and milling operations. Combined with the included intelligent nesting software, you can maximize material yield while minimizing programming time, making your entire operation leaner and more profitable.

SL1625FM Technical Specifications

Parameter | Specification |

Model | SL1625FM |

Working Area | 1600mm × 2500mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Material Fixation | Vacuum Pump & Table |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

Applicable Materials | EVA, EPE, PU, EPS, XPS, XPE, EPDM, PVC Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Warranty | 3 Years |

The Ultimate Solution for High-Value Foam Applications

The ability to both cut and mill opens up a new world of manufacturing possibilities.

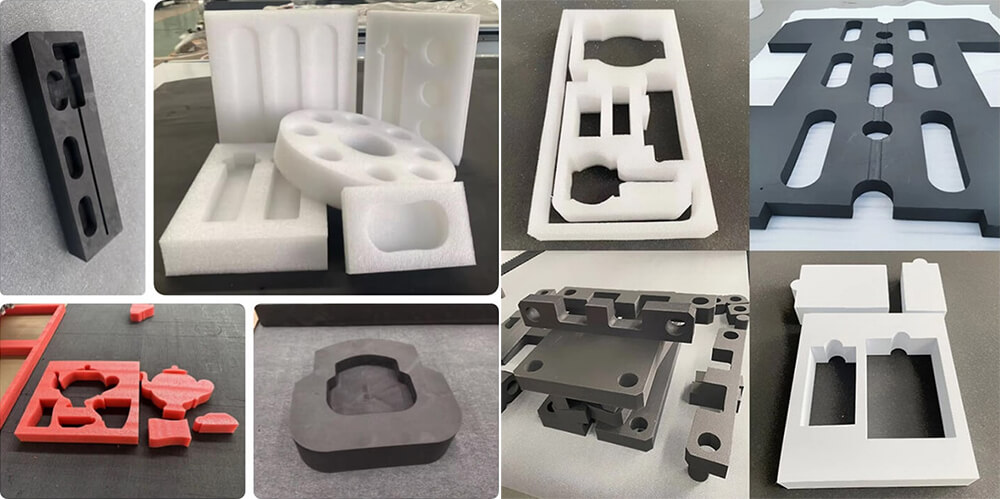

Custom Packaging & Case Inserts: The perfect machine for creating high-end protective packaging, tool control inserts (shadow boards), sales demo kits, and cases for electronics, medical devices, and military equipment.

Prototyping & Mold Making: Rapidly create detailed product mockups and low-density foam molds (plugs) for composites or casting applications.

Signage & Theatrical Props: Mill 3D logos, engraved text, and complex shapes from rigid foams like EPS and XPS for displays and props.

Specialty Components: Manufacture advanced parts like orthotics, automotive NVH components with sound-dampening channels, and custom furniture supports.

![foam-cutting-machine foam-cutting-machine]()

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our specialists understand the nuances of both cutting and milling foam. We will guide you to the ideal configuration, including the right milling bits and cutting blades for your specific materials and applications.

A Fully Integrated System: You receive a turnkey solution. The machine, software, tools, and vacuum system are designed to work in perfect harmony, ensuring you are productive from day one.

Global Installation & On-Site Training: Our factory-certified technicians provide professional installation and comprehensive training for your team, covering software, operation, and maintenance.

Authoritative 3-Year Warranty: We stand behind the superior engineering and durable components of our machines with an industry-leading 3-year warranty, securing your investment.

Lifetime Technical Support: Your long-term success is our commitment. You gain a reliable partner with lifetime access to our expert support team for any operational or technical challenges.

![]() 1625-34.jpg

1625-34.jpg

Ready to Master Complex Foam Fabrication?

Stop limiting your designs and complicating your workflow. It's time to invest in a single, powerful solution that can bring your most complex foam components to life.

Contact us today to discuss your application with a foam fabrication expert and request a custom quote and a free sample part.

Request a Quote & Free Sample Part!