SLCNC CNC Leather Cutting Machine For Genuine Leather Industry

| Table of Contents: |

1. Genuine Leather Industry Background

2. Genuine Leather Cutting Challenges 3. SLCNC Genuine Leather Cutting Solutions 3.1 Genuine Leather Software 3.2 Osillating Knife Cutting Machine

4. Genuine Leather Cutting Process 4.1 Hide Inspection and Defect Marking 4.2 Digital Hide Recognition and Edge Contouring 4.3 Automatic Nesting and Layout Optimization 4.4 Projection Verification and Manual Adjustment 4.5 Blade Settings and Cutting Parameters 4.6 Collection and Inspection 4.7 Data Logging and Material Utilization 5. Process Optimization and Best Practices 6. Quality Management and Cost Control 7. Leather Applications 8. Comparison with Traditional Methods 9. Future Trends 10. Conclusion |

1. Genuine Leather Industry Background

Genuine cowhide has always been a quality raw material for industries including upper footwear, luxury leather goods, automotive interiors and upholstered furniture. Its natural handle, durability and unique physical properties all contribute to its irreplaceable quality. Each hide is naturally unique compared to textiles or synthetic leather (e.g. thickness, shape of any edges, surface properties), which begets challenges for cutting operations—as standardized molds cannot be expected to provide acceptable levels of accuracy or precision. Instead, cutting processes need to be dynamically adjusted to address the condition of each hide.

In the past, leather cutting has been completed with hand knives, or mechanical molds; both of which have limitations.

Low Efficiency: Hand layout and cutting requires significant time, human skill and care.

Low Precision: Mistakes by human workers are inevitable resulting in irregularities with the cut pieces.

Low Material Utilization: Manual nesting cannot adjust layouts due to some cut pieces either the natural hide shape or cuts around flaws in the hide.

High Labor Demand: Cutting takes so long that physically it is hard for workers to maintain concentration.

To respond to these challenges, the use of SLCNC CNC leather cutting machines has been increasingly employed in the leather industry. These machines utilize electric motors to msupport high-speed reciprocating blades to cut leather accurately and quickly. Coupled with vacuum suction and purpose-built leather software, these machines ensure secure material placement, dynamic nesting, and easy digital visualization. The SLCNC leather software comes with features such as hide recognition, defect marking, automatic nesting, projection verification, and yield monitoring which improves efficiency, precision, and the digitalization of leather cutting.

2. Genuine Leather Cutting Challenges

Genuine cowhide presents unique challenges compared to synthetic materials. Key cutting difficulties include:

![leather-cutting-machine leather-cutting-machine]()

2.1 Irregular Shape

Each hide has unique edges, often wavy or notched. Unlike textiles, hides cannot be laid perfectly flat without careful alignment.

2.2 Variations in Thickness and Fiber Structure

Hides are not uniform in thickness or density, as the back side will generally be thicker and more resilient than the belly side. All these factors have an impact on your cutting depth and cutting speed.

2.3 Erratic Defects

Hides may have insect bites, scars, marks, veins, wrinkles, or patches of loose grain. If you cut over any kinds of defects it is likely to impact the quality of the finished product and bring harm to the appearance.

2.4 Matched-Pair Requirements

Products such as shoes, and handbags, often times require the pieces to be cut from adjacent areas to ensure the color, grain, and pattern will match. Thus the need for hide mapping becomes essential.

2.5 High Material Value

Cowhide is expensive. Waste due to poor nesting, cutting errors, or defective areas directly impacts cost. Maximizing material utilization is critical for profitability.

3. SLCNC Genuine Leather Cutting Solutions

| 3.1 Genuine Leather Software The SLCNC software integrates hardware controls and provides intelligent process management: Hide recognition: Industrial cameras scan the hide to generate digital contours. Defect marking: Operators can highlight flaws, which the system avoids during nesting. Automatic nesting: Optimizes layout to maximize yield and minimize waste. Projection verification: Ensures visual confirmation before cutting. Yield tracking and reporting: Calculates material utilization and provides data for cost management. |

| 3.2 Oscillating Knife Cutting Machine The genuine leather cutting machine is an essential instrument in contemporary leather manufacturing. Its primary elements consist of the following: oscillating knife: This component oscillates quickly upward and downward to provide clean cuts of leather.

Vacuum suction worktable: The vacuum pressure allows the leather to be held firmly to the table surface, preventing movement during the cutting process. Industry camera: Used to take photos of leather and then transmit them to leather software for subsequent contour recognition and layout. Projector: Projects the layout patterns onto the hide, making checking the leather placement intuitive for the operator. CNC Controller: Moves and cuts to very precise cutting paths in the leather based on the digital layout data used by the software. |

This hardware-software integration establishes a full digital-to-automated leather cutting workflow. |

4. Genuine Leather Cutting Process

![leather cutting machine leather cutting machine]() | 4.1 Leather Inspection and Defect Marking Operators spread the hide flat and inspect for defects such as scars, insect bites, marks, veins, and wrinkles. Defective areas are highlighted using fluorescent pens or directly in the SLCNC software. This step prevents accidental cutting into substandard regions. Edge areas that are too damaged should be marked as unusable or categorized by grade. |

![genuine leather cutting machine genuine leather cutting machine]() | 4.2 Leather Recognition and Edge Contouring Industrial cameras capture high-resolution images of each hide, generating vector contours in SLCNC software. Operators review and adjust contours if necessary, ensuring accurate boundaries for nesting. Accurate hide mapping is crucial for maximizing material usage and achieving precision cutting. |

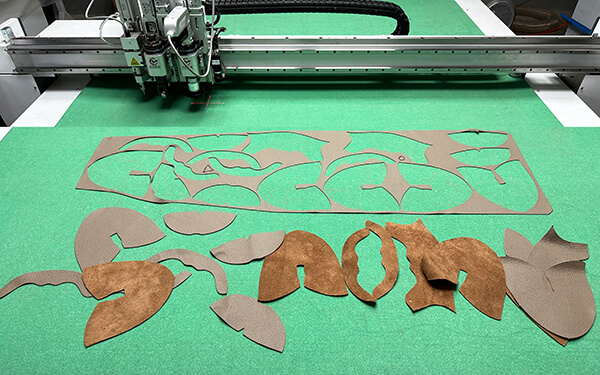

![CNC leather cutting machine CNC leather cutting machine]() | 4.3 Automatic Nesting and Layout Optimization After importing CAD patterns: Software automatically nests components based on hide shape and defect locations. Priority is given to high-grade hide areas for critical parts. Defects are avoided while maximizing material utilization. |

![CNC leather cutter machine CNC leather cutter machine]() | 4.4 Projector Verification and Manual Adjustment The software projects the layout onto the hide: Operators confirm that no pieces overlap defects.

Grain direction and orientation are checked. Minor adjustments are made if necessary, achieving a balance between automation and human expertise. |

![leather cutting machine leather cutting machine]() | 4.5 Tools Setting and Cutting Parameters Blade selection:

Standard leather: straight vibrating blade. Thick or hard leather: reinforced blade or higher vibration amplitude. Cutting parameters:

Depth: Slightly greater than thickness. Speed: Adjusted for thickness; slower for thick areas, faster for thin areas. Pressure & amplitude: Tuned to ensure clean edges without tearing. Auxiliary cutting functions:

Punching holes for stitching or alignment. |

![automatic leather cutting machine automatic leather cutting machine]() | 4.6 Collection and Inspection After cutting: Release the vacuum and remove pieces. Sort by type or grade. Inspect edges for completeness. Re-cut defective pieces after adjusting parameters if needed. |

4.7 Data Logging and Material Utilization

Software records:

Hide contours and defect positions.

Nesting layouts and cut data.

Material utilization metrics.

This allows for:

Process traceability.

Cost management and yield analysis.

Continuous improvement of nesting algorithms.

5. Process Optimization and Best Practices

5.1. Combine automated nesting with operator expertise for optimal results.

5.2. Accurate defect marking is essential to minimize waste.

5.3. Regular blade maintenance ensures consistent quality.

5.4. Adjust vacuum suction to prevent hide movement.

5.5. Analyze historical data to refine nesting and improve utilization.

6. Quality Management and Cost Control

6.1 Quality metrics

Cutting precision and edge neatness.

Defect avoidance rate.

Consistency across paired pieces.

6.2 Cost control

Maximize material utilization.

Minimize scrap and rework.

Reduce labor costs through automation.

6.3 Data-driven management

Integrate software yield reports with ERP systems.

Analyze material consumption trends.

Identify opportunities for continuous process improvement.

7. Leather Applications

![genuine-leather-cutting-machine genuine-leather-cutting-machine]()

7.1 Footwear

High-end shoes require paired pieces with consistent grain and color.

Vibrating knife cutting ensures symmetry and reduces wastage by 15%.

7.2 Automotive Interiors

Leather seats and panels require precise cuts to match curves and patterns.

SLCNC genuine leather cutting machine combined with SLCNC software allow rapid prototyping and mass production.

7.3 Furniture and Luxury Goods

Custom furniture and handbags demand defect-free surfaces and optimal material use.

Automatic nesting reduces waste and maintains consistent quality.

8. Comparison with Traditional Methods

| Method | Efficiency | Precision | Material Utilization | Labor Intensity |

| Manual cutting | Low | Variable | Low | High |

| Mold cutting | Medium-High | Medium | Medium | Medium |

| SLCNC digital cutter | High | High | High | Low |

![]()

9. Future Trends

AI-enabled defect detection: Real-time blemish detection is automatically identified.

Optimized nesting algorithms: These algorithms will continue to improve yield using machine learning.

Robotics integration: Automated loading and unloading utilizing vibrating knife technology will be adopted.

Digital factory integration: Data collection, traceability, and remote monitoring aligned with Industry 4.0 will be utilized.

10. Conclusion

The combination of SLCNC leather software and SLCNC automatic leather cutting machine embodies a radical transition from manually cutting leather to cutting leather using intelligent automation. The key advantages of cutting leather in this manner include:

Increased cutting accuracy and consistency.

Enhanced material utilization and waste elimination.

Reduced labor requirements and increased productivity.

Data-driven, traceable processes for continuous improvement.

As technologies involving AI and industrial big data continue to advance, leather cutting will continue to become more intelligent, with automatic defect detection, optimized nesting, and real-time monitoring. These combined advances will enhance production quality, improve cost reduction, and propel the leather industry to a smarter manufacturing approach embedded in more sustainable practices and principles.