Eliminate Dust & Fumes: The SL1390FF Digital EPS Foam Cutting Machine

Working with Expanded Polystyrene (EPS) foam is a battle against mess and imprecision. Manual cutting creates a "snowstorm" of static-charged beads that are impossible to contain. Traditional hot-wire cutters are slow, produce uneven melted edges, and release hazardous styrene fumes, posing a risk to your operators and product quality.

The SL1390FF Digital Cutting Machine is the definitive solution for modern EPS fabrication. It replaces outdated, messy methods with a dust-free, fume-free digital process, empowering you to create complex, accurate parts from EPS blocks with unprecedented speed and cleanliness.

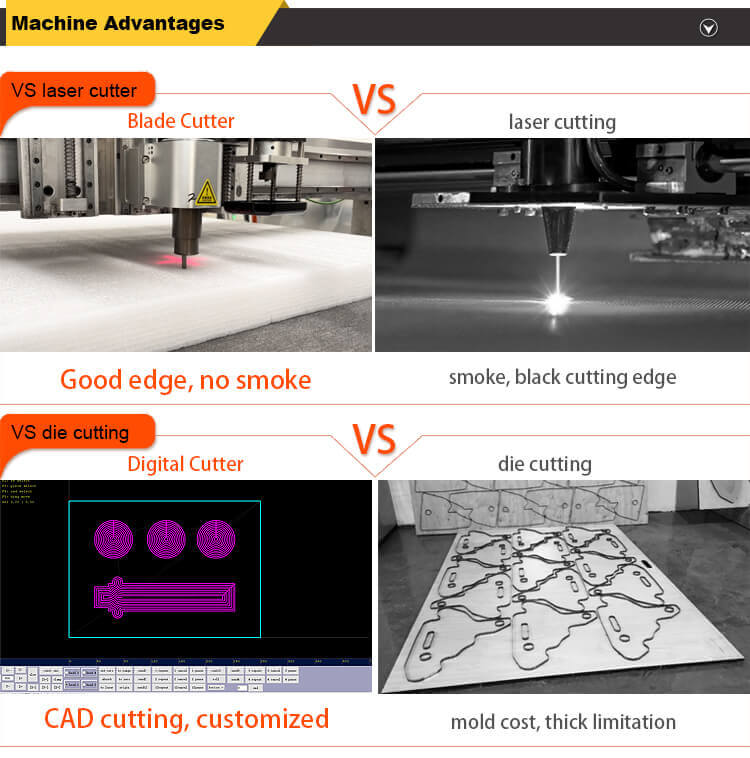

Core Advantages: Engineered for Flawless EPS Processing

The SL1390FF is purpose-built to overcome the specific challenges of cutting low-density foams like EPS.

1. Clean, Dust-Free Cutting with an Oscillating Knife

This is the game-changer for your workshop. The SL1390FF uses a high-frequency oscillating knife that slices cleanly through EPS without generating heat. This completely eliminates melting, toxic fumes, and the frustrating mess of foam beads. You get a cleaner, safer work environment and a perfectly finished product edge, every single time.

2. Unmatched Precision for Complex Shapes

Lightweight EPS blocks are notoriously difficult to hold and cut accurately. The SL1390FF solves this with a powerful vacuum table that holds the material firmly in place. Combined with the precision of the Japanese servo motors, the machine achieves a cutting tolerance of ±0.1mm. This allows you to produce intricate protective packaging inserts, detailed foundry patterns, and complex 3D shapes that are simply impossible to achieve with manual or hot-wire methods.

3. Integrated Milling for Pockets & 3D Details

Go beyond simple 2D cutting. The SL1390FF is equipped with a versatile high-speed milling tool alongside the cutting knife. This dual-tool capability allows you to mill pockets, create channels, add chamfers, and produce detailed 3D reliefs. It is the perfect feature for creating multi-part assemblies, detailed architectural models, or the complex gating and runner systems required for lost-foam casting patterns.

![foam cutting machine foam cutting machine]()

SL1390FF Technical Specifications

Parameter | Specification |

Model | SL1390FF |

Working Area | 1300mm × 900mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Work Table | Vacuum Table |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

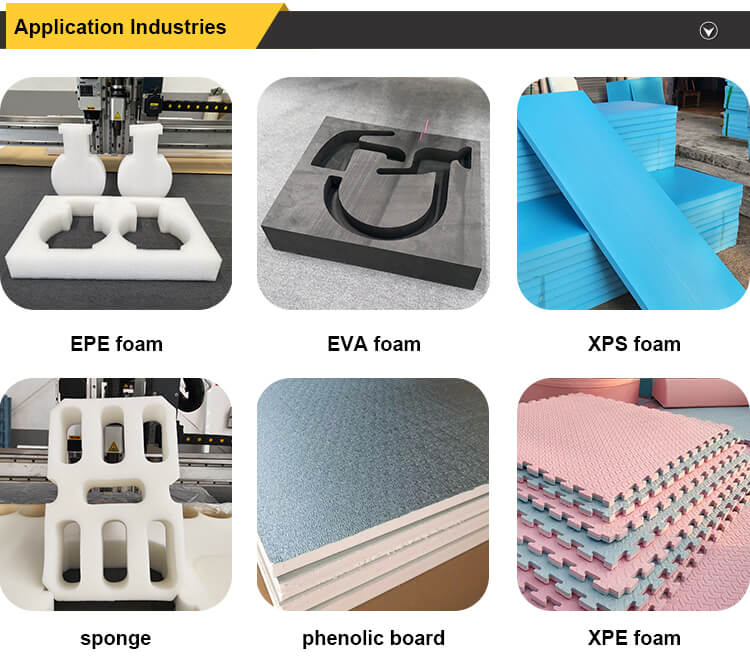

Applicable Materials | EPS, XPS, EPE, EVA, PVC Foam, EPDM, XPE Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Gross Weight | 700kgs |

Warranty | 3 Years |

The Ultimate Tool for a World of EPS Applications

The clean, precise, and efficient cutting of the SL1390FF makes it a vital asset for numerous industries.

Protective Packaging: Design and produce high-performance, custom-fit EPS inserts for fragile electronics, medical equipment, and high-value consumer goods.

Foundry & Lost-Foam Casting: Create highly accurate, complex EPS patterns for casting engine blocks, manifolds, and other intricate metal parts.

3D Signage & Displays: Fabricate large, lightweight 3D letters, logos, and point-of-purchase displays with crisp, clean edges.

Architectural Models & Props: Build detailed, multi-layered architectural models and lightweight, easily-handled props for film and theater.

Insulation & Geofoam Blocks: Cut custom shapes for building insulation, void-fill applications, and civil engineering projects.

![foam cnc cutter machine foam cnc cutter machine]()

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our specialists understand the unique properties of EPS and other foams. We will guide you to the perfect machine configuration, including the optimal blades and milling bits for your specific needs.

A Fully Integrated System: You receive a turnkey solution. The machine, intelligent nesting software, tools, and vacuum system are all designed to work in perfect harmony for maximum efficiency right out of the box.

Global Installation & On-Site Training: Our factory-certified technicians provide professional installation and comprehensive training for your team, ensuring you can operate the machine safely and effectively from day one.

Authoritative 3-Year Warranty: We stand behind the superior engineering and durable components of our machines with an industry-leading 3-year warranty, securing your investment.

Lifetime Technical Support: Your long-term success is our commitment. You gain a reliable partner with lifetime access to our expert support team for any operational or technical challenges.

![digital cutting machine factory digital cutting machine factory]()

Ready to Revolutionize Your EPS Foam Fabrication?

Stop wasting time cleaning up messes and compromising on quality. It's time to invest in a cleaner, faster, and more precise future for your business.

Contact us today to discuss your application with an EPS cutting expert and request a custom quote and sample cut.

Request a Custom Quote & Sample Cut!