Unleash Your Creativity: The SL1325FF Digital EVA Foam Cutting Machine

Working with EVA foam demands precision. Whether you are crafting intricate cosplay armor, fabricating non-slip marine decking, or designing custom case inserts, the quality of your cut defines the final product. Manual cutting with a utility knife is slow and produces inconsistent, beveled edges. Traditional die-cutting is prohibitively expensive for custom work and makes prototyping impossible.

The SL1325FF Digital Cutting Machine is the ultimate solution for modern EVA foam fabrication. It replaces manual labor and expensive dies with digital precision, empowering you to produce perfect, complex parts faster and more efficiently than ever before.

Core Advantages: Engineered for Flawless EVA Fabrication

The SL1325FF is built from the ground up to master the unique challenges of cutting EVA foam.

1. Perfect, Clean Edges with Oscillating Knife Technology

Forget the melted edges from lasers or the rough finish from manual cutting. The SL1325FF uses a high-frequency oscillating knife that slices through EVA foam with incredible speed and precision. This process generates no heat, resulting in perfectly clean, vertical edges and sharp corners every time. It’s the secret to achieving a professional, finished look on every part you produce.

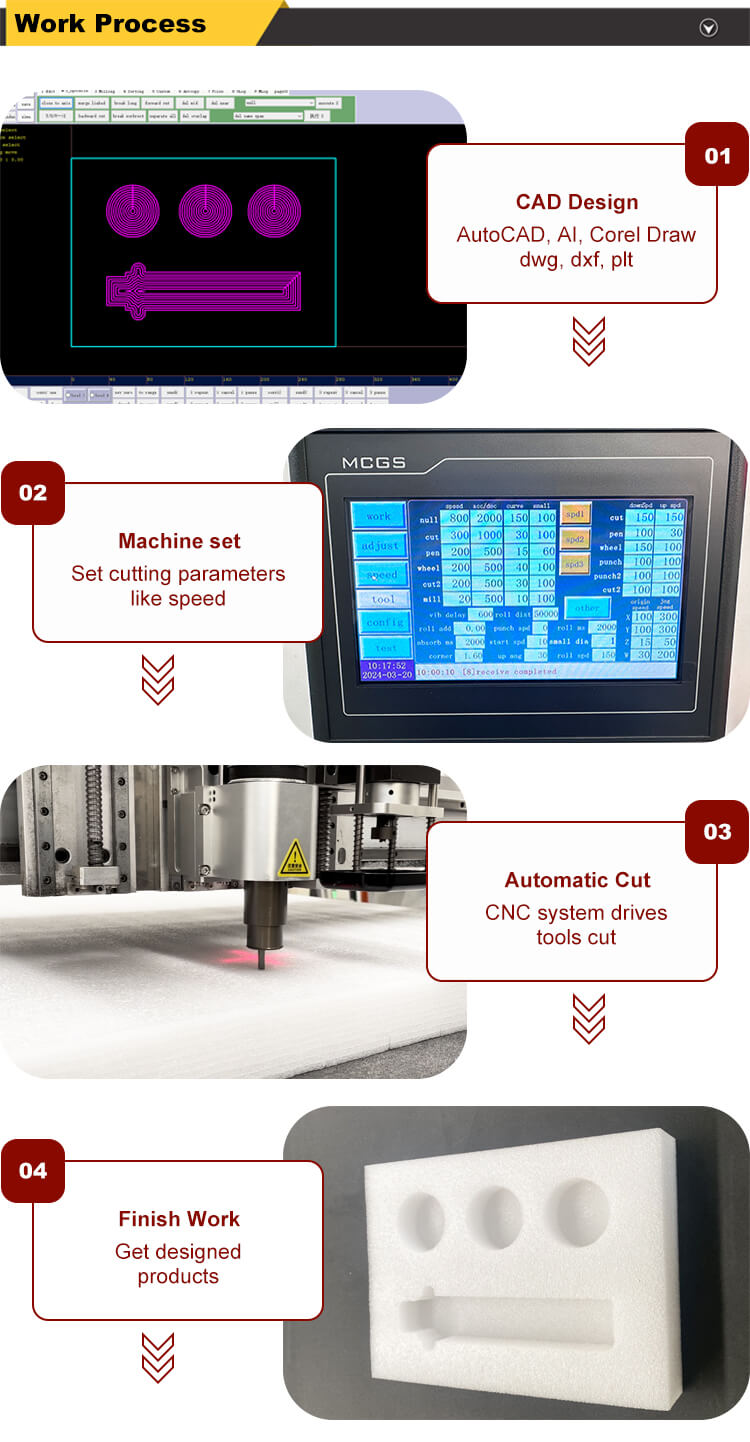

2. From Digital Design to Physical Part in Minutes

Embrace total creative freedom. The SL1325FF operates directly from your CAD, CorelDraw, or AI files, eliminating the need for physical dies. This die-less workflow means you can create a one-off prototype, handle a small custom run, or launch into full production with zero tooling costs. Respond instantly to client needs and design changes with unparalleled agility.

3. Add Detail & Texture with Precision Milling

Go beyond simple cutouts. The SL1325FF comes equipped with a high-speed milling tool, allowing you to create grooves, bevels, channels, and textured patterns. This is perfect for fabricating realistic faux-teak marine decking, adding detailed scoring lines to cosplay armor, or creating recessed pockets in multi-layer foam inserts.

![foam sheet cutting machine foam sheet cutting machine]()

SL1325FF Technical Specifications

Parameter | Specification |

Model | SL1325FF |

Working Area | 1300mm × 2500mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Work Table | Vacuum Table (Regional Adsorption) |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

Applicable Materials | EVA, EPE, EPS, XPS, PVC Foam, EPDM, XPE Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Gross Weight | 1300kgs |

Warranty | 3 Years |

The Ultimate Tool for a World of EVA Applications

The precision and versatility of the SL1325FF make it the go-to machine for a diverse range of markets.

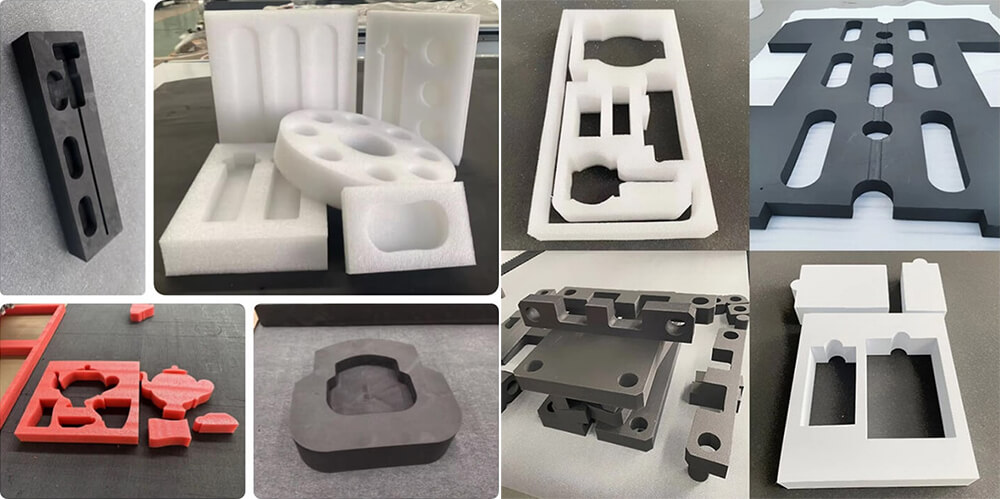

Cosplay & Prop Making: Cut complex armor pieces, detailed weapon components, and layered costume elements with perfect accuracy.

Marine Flooring & Upholstery: Fabricate custom non-slip boat decking (e.g., SeaDek alternatives), helm pads, and coaming bolsters with precision grooves and bevels.

Custom Packaging & Case Inserts: Design and produce perfect-fit protective inserts for tools, electronics, and sensitive equipment.

Orthotics & Footwear: Manufacture custom insoles, midsoles, and other orthopedic components from specialized EVA sheets.

Sports & Safety Equipment: Produce gym flooring, martial arts mats, protective padding, and helmet liners.

![foam-cutting-machine foam-cutting-machine]()

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our specialists understand the nuances of cutting different densities and types of EVA foam. We will help you configure the perfect system with the right blades and milling bits for your specific applications.

A Fully Integrated System: You receive a turnkey solution. The machine, tools, nesting software, and vacuum system are designed to work in perfect harmony for immediate productivity.

Global Installation & On-Site Training: Our factory-certified technicians provide professional installation and comprehensive training for your operators, ensuring your team can leverage the machine's full potential safely and effectively.

Authoritative 3-Year Warranty: We stand behind our robust engineering and high-quality components with an industry-leading 3-year warranty, giving you complete peace of mind in your investment.

Lifetime Technical Support: Your success is our long-term commitment. You gain a reliable partner with lifetime access to our expert support team for any operational or technical questions.

Ready to Perfect Your EVA Foam Projects?

Stop struggling with inaccurate manual cuts and expensive dies. It's time to upgrade your workshop with the speed, precision, and flexibility of digital cutting.

Contact us today to discuss your application with an EVA cutting expert and receive a customized quote.

Request Your Free Consultation & Quote!