Eliminate Dies, Automate Production: The SL1625FC EPDM Foam Cutter

The high costs and long lead times of die-cutting are a major bottleneck for modern manufacturing. For every new gasket, seal, or insulator design, you face expensive tooling charges and weeks of waiting. This process kills agility, makes prototyping impractical, and locks you into large production runs. For manufacturers working with EPDM and other industrial foams, this inflexibility is a constant barrier to efficiency and innovation.

The SL1625FC Dieless EPDM Foam Cutting Machine is engineered to break this cycle. Featuring a fully integrated auto-feeding conveyor system, it provides a seamless, automated workflow from material roll to perfectly finished part. Embrace the future of on-demand, high-precision foam fabrication.

Core Advantages: Built for Continuous, High-Throughput Production

The SL1625FC is not just a cutter; it's an automated production system designed for industrial-scale efficiency.

1. The Power of Dieless Flexibility

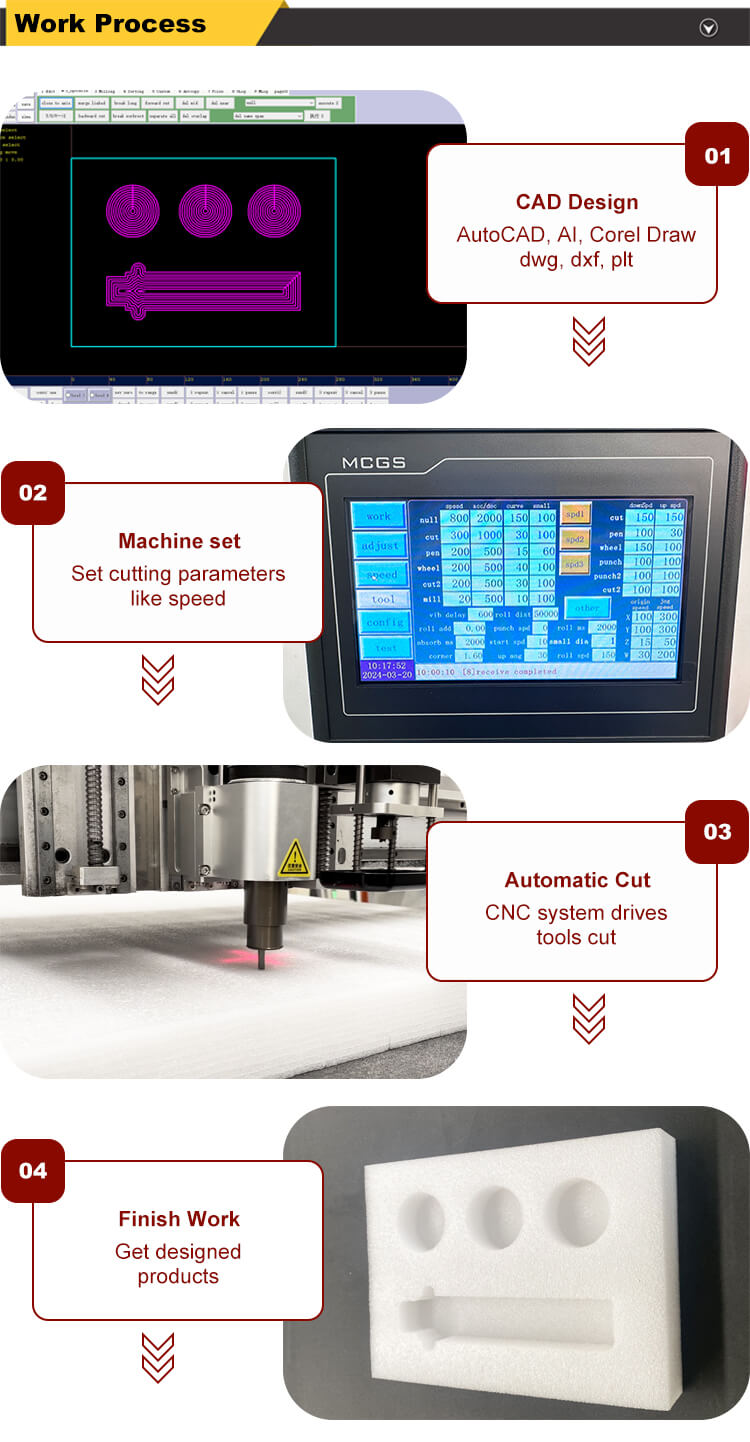

This is your escape from the limitations of traditional tooling. The SL1625FC operates directly from your CAD files, allowing you to go from a new design to a finished product in minutes.

Zero Tooling Costs: Save thousands on die manufacturing and storage.

Instant Design Changes: Modify a part or create a new prototype on the fly.

Profitable Small Batches: Produce custom orders and short runs as efficiently as large ones.

2. Fully Automated, Continuous Cutting with an Auto-Feed Conveyor

This feature transforms your workflow from batch processing to continuous, uninterrupted production. The conveyor belt automatically pulls material from a roll or long sheet onto the cutting area. As one section is cut, the system advances the material for the next, enabling true "lights-out" manufacturing. Combined with a powerful vacuum pump that secures the EPDM foam during cutting, this system ensures maximum throughput with minimal operator intervention.

3. Uncompromising Precision for Functional Components

EPDM gaskets and seals require tight tolerances to perform correctly. The SL1625FC delivers ±0.1mm accuracy thanks to its robust construction, precise Japan servo motors, and a high-frequency oscillating knife. The blade slices cleanly through dense materials like EPDM without distortion, producing sharp corners and smooth edges essential for creating a perfect seal.

![foam sheet cutting machine foam sheet cutting machine]()

SL1625FC Technical Specifications

Parameter | Specification |

Model | SL1625FC |

Working Area | 1600mm × 2500mm (Length is unlimited with conveyor) |

Work Table | Auto-Feeding Conveyor |

Material Fixation | Vacuum Pump |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

Applicable Materials | EPDM, PU, EPE, EVA, EPS, XPS, PVC, XPE Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Warranty | 3 Years |

The Go-To Solution for Industrial Foam Fabrication

The automation and precision of the SL1625FC make it a critical asset for manufacturers who demand quality and efficiency.

Automotive: Produce gaskets, seals, weather stripping, acoustic insulation, and vibration dampening pads.

HVAC & Construction: Fabricate custom duct liners, pipe insulation, expansion joints, and weather-resistant seals.

Industrial Manufacturing: Create precision machine gaskets, enclosure seals, protective padding, and vibration mounts.

Electronics: Cut custom foam inserts for packaging, EMI/RFI shielding gaskets, and enclosure seals.

Sports & Marine: Manufacture durable, weather-resistant padding and flooring components.

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our team specializes in cutting industrial materials like EPDM. We will help you configure the ideal system—from the blade type to the vacuum power—to perfectly match your production needs.

A Fully Integrated System: You receive a turnkey solution. The machine, conveyor, nesting software, and vacuum system are pre-configured to work together flawlessly, ensuring you are productive from day one.

Global Installation & On-Site Training: Our certified technicians provide professional installation and train your team on machine operation, software, and maintenance for a fast and successful implementation.

Authoritative 3-Year Warranty: We are so confident in the robust construction and reliability of our machines that we back the SL1625FC with an industry-leading 3-year warranty for your peace of mind.

Lifetime Technical Support: Your success is our mission. You gain a dedicated partner with lifetime access to our expert support team for any operational or application questions.

Ready to Eliminate Dies and Automate Your EPDM Cutting?

Step into a more flexible, efficient, and profitable era of manufacturing. Let the SL1625FC handle the complexities of foam fabrication so you can focus on growing your business.

Contact us today to discuss your application with an industrial foam cutting specialist and request a quote and a free material test.

Request a Quote & Free Material Test!