The Future of Foam Fabrication: The SL1625FF Digital Cutting Machine

Creating custom EPE foam packaging inserts and components is a constant battle between cost, speed, and precision. Traditional die-cutting is expensive and inflexible, requiring a new die for every design change and making prototypes or small runs unprofitable. Manual cutting is slow, inconsistent, and incapable of producing the complex, multi-level pockets required for high-value products.

The SL1625FF Digital Cutting Machine is the versatile, die-less solution engineered to overcome these limitations. It combines high-speed cutting and precision milling to give you complete control over your foam fabrication process, from a single prototype to full-scale production.

Core Advantages: Engineered for Custom Foam Products

The SL1625FF is designed to make your operation more agile, precise, and profitable.

1. Unlock True Customization: The Die-Less Cutting Advantage

Say goodbye to the cost and lead times of die manufacturing. The SL1625FF operates directly from your CAD files (AutoCAD, SolidWorks, etc.). This digital workflow allows you to go from design to finished product in minutes, not weeks. Offer your clients unlimited customization, produce one-off prototypes instantly, and adapt to design changes on the fly—all while eliminating tooling costs.

2. Beyond Cutting: Precision Milling for Perfect-Fit Inserts

This is the feature that sets your products apart. The SL1625FF is equipped with both a high-frequency oscillating cutting tool and a high-speed milling tool. This dual capability allows you to not only cut complex outlines but also to mill precise pockets, recesses, and multi-depth cavities. Create perfect, secure nests for electronics, tools, medical devices, and other sensitive components with unmatched accuracy.

3. Maximize Material Yield & Stability

Foam is your primary cost—don't waste it. The included intelligent nesting software automatically arranges your parts to maximize material usage on every board. The large 1600mm x 2500mm regional vacuum table firmly secures the foam during processing, preventing material shift and ensuring every cut is perfectly accurate to ±0.1mm, even at speeds up to 1500mm/s.

SL1625FF Technical Specifications

Parameter | Specification |

Model | SL1625FF |

Working Area | 1600mm × 2500mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Work Table | Vacuum Table (Regional Adsorption) |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

Applicable Materials | EPE, EVA, EPS, XPS, PVC Foam, EPDM, XPE Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Gross Weight | 1500kgs |

Warranty | 3 Years |

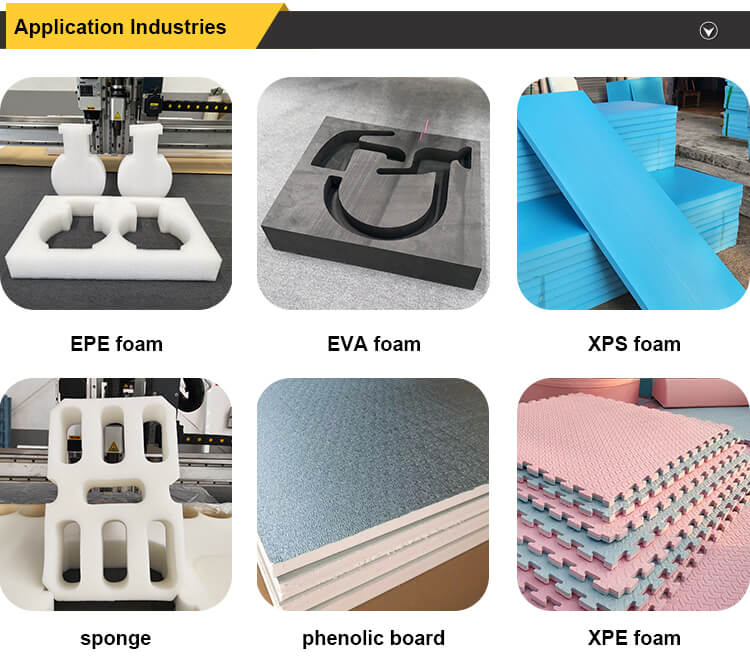

The Ideal Solution for a World of Foam Applications

The versatility of the SL1625FF makes it the essential tool for a wide range of industries.

Custom Protective Packaging Inserts: Manufacturing high-quality inserts for electronics, medical devices, luxury goods, and industrial parts.

Tool Control & Case Inserts: Creating precision-milled foam interiors for toolboxes, flight cases (e.g., Pelican, SKB), and equipment transport.

Furniture & Upholstery Components: Cutting foam cores, padding, and structural elements for seating and furniture manufacturing.

Sports & Leisure Products: Fabricating components for gym mats, body armor, helmet liners, and buoyancy aids.

Automotive Interiors: Prototyping and producing foam-based components like gaskets, seals, and acoustic dampening panels.

![foam cnc cutter machine foam cnc cutter machine]()

The SLCNC Partnership: Your Complete Foam Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our team has deep knowledge of cutting various foam types. We will work with you to configure the ideal system with the right cutting and milling tools for your specific materials and products.

A Fully Integrated System: You receive a turnkey solution. The machine, tools, software, and vacuum system are pre-configured to work together seamlessly, ensuring you are productive from day one.

Global Installation & On-Site Training: Our certified technicians provide professional installation and train your team on machine operation, software use, and maintenance, guaranteeing a fast and successful implementation.

Authoritative 3-Year Warranty: We are so confident in the robust construction and reliability of our machines that we back the SL1625FF with an industry-leading 3-year warranty for your peace of mind.

Lifetime Technical Support: Your success is our mission. You gain a dedicated partner with lifetime access to our expert support team for any operational or application questions.

![digital cutting machine factory digital cutting machine factory]()

Ready to Revolutionize Your Foam Fabrication?

Stop relying on expensive dies and inaccurate manual methods. Discover how the SL1625FF can deliver perfect, custom foam products faster and more profitably.

Contact us today to discuss your application with a foam cutting specialist and get a free production analysis.

Get Your Custom Foam Cutting Solution!