Why Choose SLCNC CNC Gasket Cutting Machine

| In the field of gasket manufacturing, the choice of cutting process is directly related to product quality, production efficiency and cost control. As an advanced cutting equipment, SLCNC CNC gasket cutting machine has shown significant advantages in many aspects due to its technical characteristics, which will be elaborated in detail below.

![未标题-1]()

|

1. Reduce costs

1.1 Reduce material waste

SLCNC gasket CNC cutter is equipped with intelligent layout software, which can optimize the layout according to the shape and size of the gasket, improve material utilization, and save more than 15% of materials compared with manual layout. The cost of rubber gasket materials is high, and the cost saved by optimizing the layout is considerable.

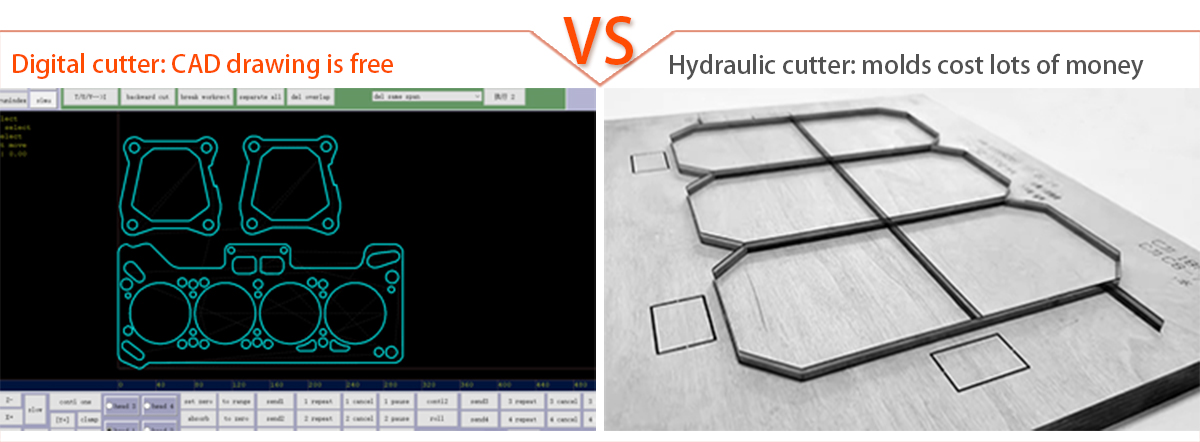

1.2 Saving mold costs

Compared with hydraulic die cutting, the biggest advantage of our CNC gasket making machine is that there is no need to make molds. The mold making cost is high, especially the molds of complex-shaped gaskets are more expensive. The mold cost can reach tens of thousands or even hundreds of thousands of yuan per year, and the mold needs to be remade when the product design changes. Our gasket CNC machine can cut gaskets of different shapes by modifying the design drawings, which greatly reduces the mold cost and has obvious advantages for small-batch and multi-variety production enterprises.

![cnc-gasket-cutter cnc-gasket-cutter]()

1.3 Save labor costs

The cutting process of the gasket cutting machine does not require manual work, and the equipment operator can collect and pack the cut gaskets. In the current situation of difficult recruitment and expensive labor, a lot of labor costs can be saved.

2. High precision

Our gasket cutting machine relies on an advanced CNC system to accurately control the tool movement trajectory. It uses high-precision Japanese servo motors and drives, rack and square rail transmission systems, and an integrated welded bed to ensure the cutting accuracy of the machine. This high-precision cutting ensures that the connecting parts fit tightly and effectively prevents liquid leakage.

![gasket cutting machine gasket cutting machine]()

3. Perfect cutting edge

The knife blade of our gasket cutter machine quickly cuts off the material through high-frequency vibration, and the cutting edge is smooth and flat without burrs, without the need for secondary grinding, saving processing time and cost. In industries such as aerospace that have strict requirements on sealing performance, smooth edges ensure that the gasket maintains a good sealing effect in extreme environments.

![gasket cutter machine gasket cutter machine]()

4. High degree of automation

| SLCNC CNC gasket cutter is a computer-controlled automatic cutting machine, and can be equipped with an automatic feeding function to achieve continuous automatic production. The operator only needs to import the gasket design drawings, and the machine can automatically complete the cutting according to the preset program, reducing manual intervention and labor intensity.

![未标题-1]()

|

5. Wide material adaptability

SLCNC CNC gasket machine can be equipped with a variety of cutting tools, such as vibration knives, pneumatic knives, milling cutters, etc. And the cutting speed can be adjusted, so it can cut gaskets of various materials and thicknesses.

![cnc-gasket-cutting-machine cnc-gasket-cutting-machine]()

5.1 Compatible with a variety of gasket materials

Our gasket machine is suitable for cutting a variety of gasket materials such as rubber, silicone, polyurethane, PTFE (polytetrafluoroethylene), asbestos, graphite composite plates, etc. Whether it is soft rubber or asbestos with higher hardness, it can be easily dealt with.

5.2 Cutting of materials of different thicknesses

SLCNC gaskets cutting machine can adapt to the cutting of gasket materials ranging from as thin as 0.1mm to tens of millimeters thick. By adjusting the cutting parameters and the type of cutting tool, it can meet various thickness requirements.

![CNC-gasket-cutter-machine CNC-gasket-cutter-machine]()

6. Environmental protection

SLCNC gasket cutting machines adopt cold cutting method, and there is no dust, smoke and harmful gas generated during the cutting process, which is pollution-free to the environment, ensuring the health of operators and the quality of workshop environment.

Laser cutting vaporizes the material and produces a lot of smoke.

The miliing machine will produce dust and debris when cutting.

7. High safety performance

The gasket making machine is equipped with a variety of safety protection devices such as infrared sensing system and emergency stop button. If someone enters the dangerous area during operation, the system will immediately alarm and shut down to ensure the personal safety of the operator.

![gasket-cutting-machine-safety-devices gasket-cutting-machine-safety-devices]()

8. Excellent for customized gaskets

The gasket cutter machine has significant advantages in customizing gaskets. Through the advanced CNC system, it can quickly convert the design drawings into cutting paths, accurately cut various complex shapes, and meet diversified customization needs. Especially for processing large-sized gaskets such as ships, the hydraulic die-cutting machine is not large enough, and it is difficult to make such a large die. Our gasket cutting machine can process customized, large-sized gaskets very well.

![gasket-cnc-cutting-machine gasket-cnc-cutting-machine]()

9. Easy to management

For our CNC gasket cutting machine, it has great advantages in cutting graphics management. No matter what kind of gasket, we only need to save a CAD graphic in the computer, and naming and querying are very simple. It can be called very easily. For hydraulic die cutting machines, there are a large number of die cutters that need to be saved, which takes up a lot of space, and the management is very complicated. It is also very difficult to find a specific gasket die cutter.

![gasket-cnc-cutter-machine gasket-cnc-cutter-machine]()

10. Easy to operation

SLCNC CNC gasket cutting machine is easy to operate, so the operator's work experience and professional knowledge are rarely required. It is easy to find workers to operate the machine, and the learning time is also very short. It avoids the embarrassing situation that no one can operate the machine due to personnel loss.

11. Good after sales service

![gasket cutting machine factory gasket cutting machine factory]()