Precision Cutting for Rigid Foam: The SL1610FF CNC Cutting Machine

Fabricating with XPS foam presents a unique set of challenges. Traditional hot-wire cutters are messy, release harmful fumes, and struggle with sharp corners and intricate internal details. Manual cutting is labor-intensive, dusty, and makes achieving the consistent accuracy required for architectural models or perfectly-fit insulation nearly impossible.

The SL1610FF CNC Cutting Machine is engineered to master these challenges. It replaces outdated, hazardous methods with a clean, fast, and incredibly precise digital process, enabling you to transform XPS boards into complex components with unmatched quality and efficiency.

Core Advantages: Engineered for XPS & Rigid Foam

The SL1610FF is designed to deliver superior results and a better working environment.

1. The No-Melt, No-Fume Solution: Oscillating Knife Technology

This is the future of rigid foam cutting. Unlike hot wires that melt material and create toxic fumes, the SL1610FF utilizes a high-frequency oscillating knife. This mechanical blade slices cleanly through XPS and EPS foam, producing sharp, precise edges without heat, melting, or hazardous air quality issues. It creates a safer workshop and a higher quality product.

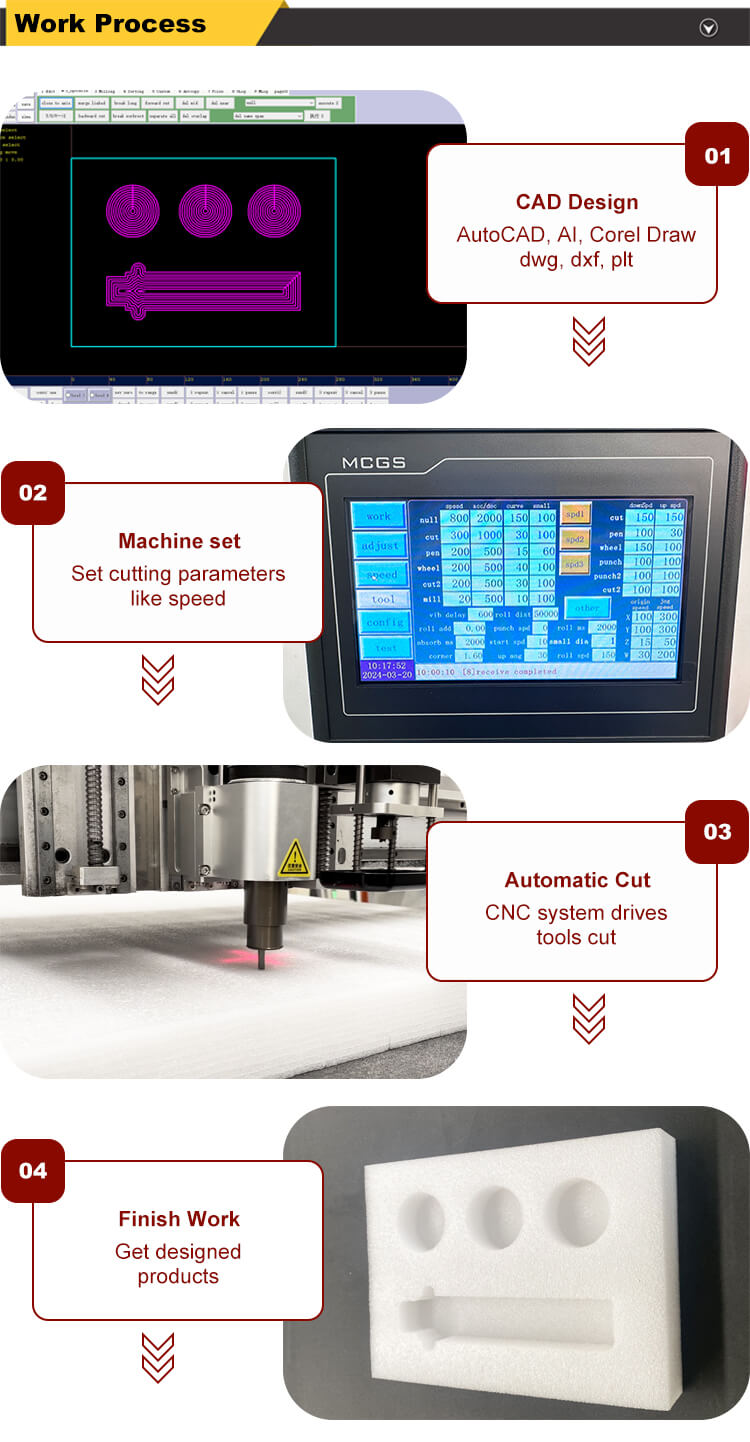

2. From Blueprint to Building Block in Minutes

Streamline your workflow from design to production. The SL1610FF works directly with your digital files from AutoCAD, SolidWorks, and other CAD programs. The powerful CAM software and intuitive controls allow you to go from a digital blueprint to a perfectly cut physical part in minutes. Eliminate time-consuming manual layouts and achieve flawless repeatability on every component.

3. Precision Milling for 3D Forms & Joinery

Unlock a new level of detail. The SL1610FF is equipped with both a cutting knife and a high-speed milling tool. This allows you to not only cut complex profiles but also to create channels, rebates, chamfered edges, and interlocking joints. This is essential for creating professional architectural models, custom-fit insulation for pipes, and dimensional signage with recessed details. The powerful vacuum table ensures the material is held perfectly flat for ±0.1mm accuracy.

![foam sheet cutting machine foam sheet cutting machine]()

SL1610FF Technical Specifications

Parameter | Specification |

Model | SL1610FF |

Working Area | 1600mm × 1000mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Work Table | Vacuum Table (Regional Adsorption) |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

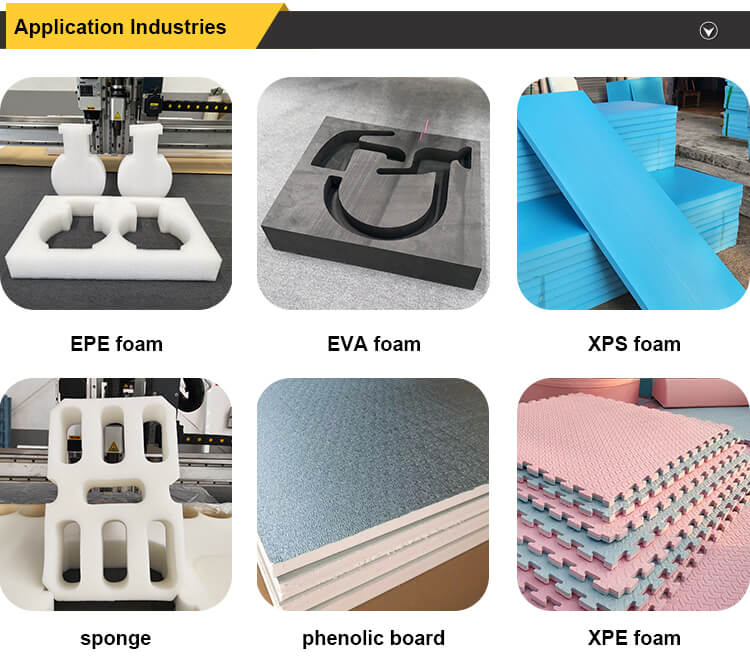

Applicable Materials | XPS, EPS, EPE, EVA, PVC Foam, EPDM, XPE Foam |

Cutting Tolerance | ±0.1mm |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Gross Weight | 900kgs |

Warranty | 3 Years |

The Ideal Machine for Demanding Applications

The clean precision of the SL1610FF makes it indispensable across multiple industries.

Architectural & Topographical Models: Create detailed building mockups, landscape contours, and urban planning models with perfectly assembled layers.

Building Insulation & HVAC: Fabricate custom-fit XPS and EPS insulation panels for walls, roofs, and complex ductwork, eliminating gaps and improving thermal efficiency.

3D Signage & Lettering: Cut crisp, dimensional logos, letters, and graphic elements for both indoor and outdoor commercial signage.

Film, Theater & Themed Environments: Rapidly produce lightweight, durable props, set pieces, and custom scenic elements.

Concrete Formwork & Molds: Use XPS as a cost-effective, easy-to-shape material for creating custom molds and form liners for concrete casting.

![foam cnc cutter machine foam cnc cutter machine]()

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our team has extensive experience cutting rigid foams. We will work with you to configure the ideal system, including the right blades and milling tools, to meet the specific demands of your projects.

A Fully Integrated System: You receive a turnkey solution. The machine, software, tools, and vacuum system are pre-configured to work together seamlessly, ensuring you are productive from day one.

Global Installation & On-Site Training: Our certified technicians provide professional installation and train your team on machine operation, software, and maintenance, guaranteeing a fast and successful implementation.

Authoritative 3-Year Warranty: We are so confident in the robust construction and reliability of our machines that we back the SL1610FF with an industry-leading 3-year warranty for your peace of mind.

Lifetime Technical Support: Your success is our mission. You gain a dedicated partner with lifetime access to our expert support team for any operational or application questions.

Ready to Master Your XPS Foam Projects?

Leave the fumes, dust, and inaccuracies of old methods behind. It’s time to embrace the clean, fast, and precise world of digital cutting.

Contact us today to discuss your application with a rigid foam cutting specialist and get a quote for your solution.

Get a Quote for Your Application!