Automate Your PU Foam Cutting: The SL1630FF Digital Solution

Working with Polyurethane (PU) foam means battling its natural tendency to compress and deform. Manual cutting results in angled, inconsistent edges and inaccurate dimensions. Vertical band saws struggle with complex shapes and blade drift. Relying on die-cutting for custom jobs is simply too slow and expensive, killing your profitability and agility. These inefficiencies lead to wasted material, rework, and a compromised final product.

The SL1630FF Automatic PU Foam Cutting Machine is the definitive answer to these challenges. It leverages advanced digital technology to replace manual guesswork and inflexible dies with a fully automated, highly precise workflow. It empowers you to transform large blocks of PU foam into perfect components, faster and more efficiently than ever before.

Core Advantages: Engineered for Flawless PU Foam Processing

The SL1630FF is purpose-built with features that master the unique properties of flexible and semi-rigid foams.

1. Flawless Vertical Cuts, Zero Compression

This is the heart of our machine's performance. The SL1630FF utilizes a high-frequency oscillating knife that slices through PU foam with thousands of precise vertical strokes per minute. This action eliminates the pushing and dragging forces that cause material compression, guaranteeing perfectly vertical, smooth edges even on the softest foams and most intricate patterns.

2. Absolute Material Stability with Regional Vacuum

Flexible PU foam sheets are prone to shifting and buckling during cutting. The SL1630FF features an intelligent regional adsorption vacuum table. This system divides the work surface into zones, concentrating powerful suction precisely under the cutting area. This locks the material firmly in place, preventing any movement and ensuring the machine can consistently deliver its ±0.1mm cutting accuracy.

3. Maximize Profitability with a Die-Less Workflow

Move from design to finished product in minutes. The SL1630FF operates directly from your CAD files (SolidWorks, AutoCAD, etc.), completely eliminating the need for expensive and time-consuming dies. Furthermore, the included intelligent nesting software automatically optimizes the layout of your parts on the foam block, significantly reducing material waste and maximizing your yield. This automated process makes your operation leaner, more profitable, and ready for mass customization.

SL1630FF Technical Specifications

![cnc foam cutting machine cnc foam cutting machine]()

Parameter | Specification |

Model | SL1630FF |

Working Area | 1600mm × 3000mm (Customizable) |

Working Tools | Oscillating Cutting Tool, High-Speed Milling Tool |

Work Table | Vacuum Table (Regional Adsorption) |

Max Cutting Speed | ≤1500mm/s |

Cutting Thickness | ≤100mm |

Applicable Materials | PU, EPE, EVA, EPS, XPS, PVC, EPDM, XPE Foam |

Cutting Tolerance | ±0.1mm |

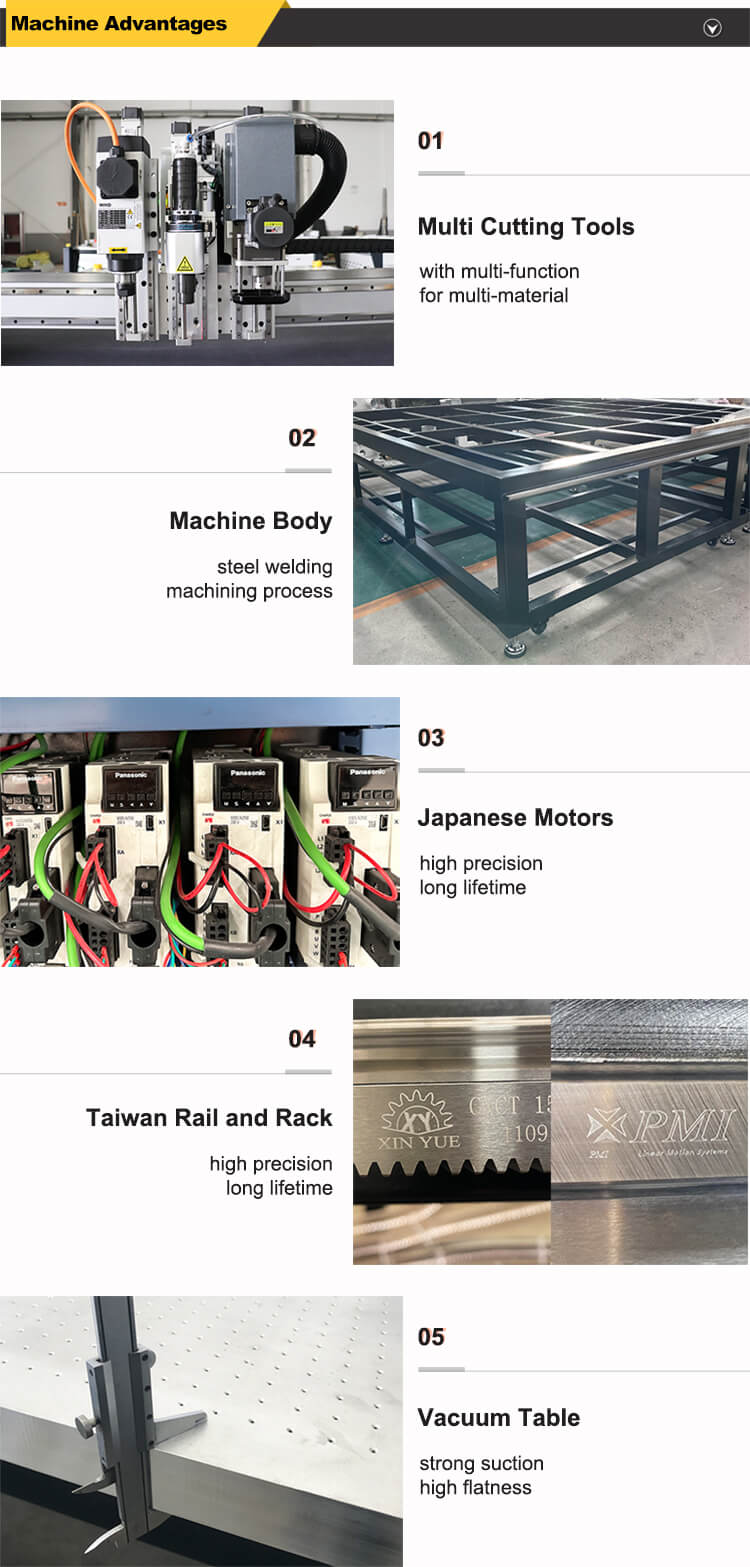

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Gross Weight | 1600kgs |

Warranty | 3 Years |

The Ultimate Tool for a World of PU Foam Applications

The speed, precision, and automation of the SL1630FF make it an indispensable asset for a wide range of industries.

Furniture & Bedding: Automate the production of sofa cushions, mattress layers, chair pads, and complex orthopedic supports with perfect repeatability.

Custom Packaging & Case Inserts: Manufacture high-end protective packaging, custom tool-control foam inserts, and component trays for sensitive electronics.

Automotive & Marine Interiors: Precisely cut components for vehicle seating, headliners, door panels, and acoustic/vibration dampening.

Sports & Safety Equipment: Produce high-performance protective padding for athletic gear, gymnastic equipment, and safety applications.

Industrial Gaskets & Insulation: Cut custom gaskets, seals, and thermal/acoustic insulation parts from a variety of industrial foams like EPDM and PVC.

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our specialists have extensive experience with the full spectrum of flexible and rigid foams. We will guide you to the ideal machine configuration, including the correct blades and software settings for your specific PU foam densities.

A Fully Integrated System: You receive a turnkey solution. The machine, intelligent nesting software, tools, and vacuum system are all designed to work in perfect harmony for maximum efficiency right out of the box.

Global Installation & On-Site Training: Our factory-certified technicians provide professional installation and comprehensive training for your team, ensuring you can operate the machine safely and effectively from day one.

Authoritative 3-Year Warranty: We stand behind the superior engineering and durable components of our machines with an industry-leading 3-year warranty, securing your investment.

Lifetime Technical Support: Your long-term success is our commitment. You gain a reliable partner with lifetime access to our expert support team for any operational or technical challenges.

Ready to Upgrade Your PU Foam Production?

Stop accepting waste and inconsistency. It's time to invest in the automated, precise, and profitable future of foam fabrication.

Contact us today to discuss your application with a PU foam cutting expert and request a custom quote and a free sample cut

Request a Quote & Free Sample Cut!