Introduction

The global market for foam cutting machines is evolving rapidly. Driven by the booming e-commerce packaging sector, the demand for insulation in green construction, and the automotive industry's need for lightweight materials, the competition among equipment manufacturers is fiercer than ever.

For businesses investing in these technologies, understanding the market landscape is crucial. It is not just about buying a machine; it is about partnering with a manufacturer who understands where the industry is headed. This article analyzes the current competitive landscape and explores how businesses can carve out a niche in a crowded market.

1. Market Overview: Growth and Dynamics

To navigate the market, we must first understand its scale and trajectory.

1.1 Market Size and Growth Trends

The foam cutting machinery market is experiencing steady growth, projected to expand significantly over the next five years. This surge is fueled by the universal need for protective packaging (EPE/EPS) and the rising standards for energy-efficient building materials (XPS insulation). As industries move away from manual labor, the demand for automated CNC solutions is the primary growth engine.

1.2 Key Market Players

The market is currently segmented into two main categories:

High-End European/North American Brands: Known for extreme precision but often come with a prohibitive price tag and high maintenance costs.

Emerging High-Tech Innovators (Asia): Manufacturers who have successfully bridged the gap, offering comparable CNC precision and reliability at a much more accessible price point, disrupting the traditional market hierarchy.

![Foam Cutting Machine Market Analysis: Strategies to Stand Out in 2026 Foam Cutting Machine Market Analysis: Strategies to Stand Out in 2026]()

2. Competitive Analysis: The Pillars of Success

In a market flooded with options, how do products distinguish themselves?

2.1 Product Differentiation

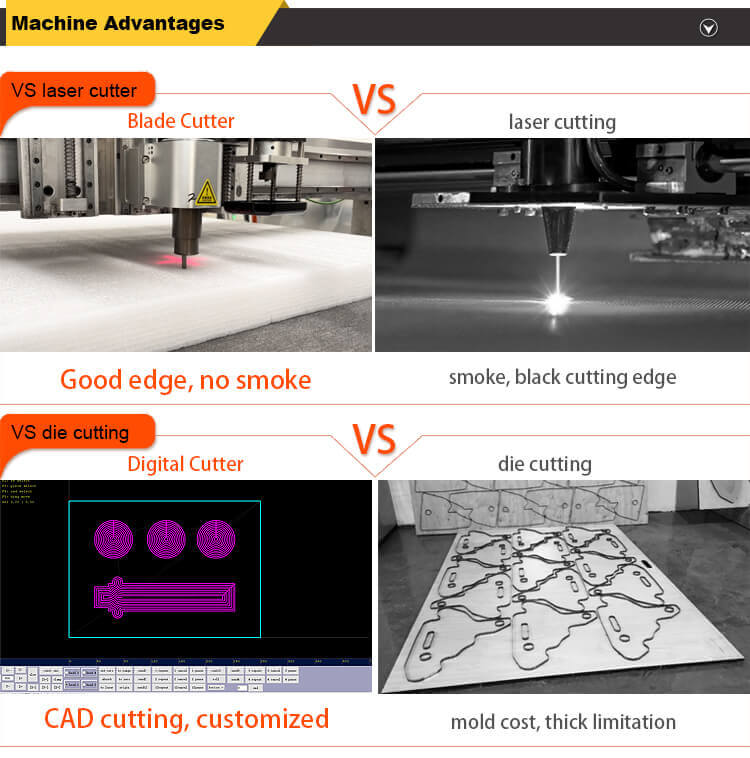

Differentiation is no longer just about "cutting foam." It is about how it cuts.

Specialization: Some machines are generalists, while others are specialists. For instance, a foam cutting machine equipped with an oscillating knife offers a clean, dust-free edge for upholstery, whereas a hot-wire cutter excels in construction blocks.

Software Integration: The leading machines now come with proprietary nesting software that integrates seamlessly with ERP systems, offering a "smart factory" solution rather than just a standalone tool.

2.2 The Price vs. Value Equation

Price competition is intense, but the "lowest price" is rarely the winner in the long run.

The Trap: Cheap machines often use inferior guide rails or motors, leading to downtime.

The Strategy: Smart buyers look at Total Cost of Ownership (TCO). A slightly more expensive machine that saves 20% on material waste and requires less maintenance offers a far better competitive advantage than a budget machine that halts production.

2.3 Service and Support as a Differentiator

In the B2B machinery market, the product is only half the package.

After-Sales: The ability to provide remote troubleshooting, quick spare parts delivery, and comprehensive training is often the deciding factor for international buyers. A machine is only profitable when it is running.

3. Opportunities and Challenges

Where is the blue ocean in this red ocean market?

3.1 Emerging Markets

New applications are creating fresh demand.

Medical & Healthcare: The need for precision-cut, sterile foam for orthotics and medical device packaging is growing.

Electronics: Anti-static (ESD) foam cutting for high-value electronics requires machines with specific handling capabilities, presenting a lucrative niche.

3.2 Technological Innovation

Innovation is the ultimate barrier to entry.

3.3 Navigating Economic Fluctuations

Economic downturns affect capital expenditure. However, this also presents an opportunity. During tough times, efficiency is king. Companies that invest in automated foam cutting machines to reduce material waste and labor costs are better positioned to weather economic storms than those relying on manual processes.

![Foam Cutting Machine Market Analysis: Strategies to Stand Out in 2026 Foam Cutting Machine Market Analysis: Strategies to Stand Out in 2026]()

Conclusion

The foam cutting machine market is crowded, but there is always room for quality and innovation. For buyers, the key is to look past the sticker price and evaluate the technological capabilities and support structure of the manufacturer.

To stand out, businesses must leverage advanced equipment that offers versatility, material efficiency, and reliability. By aligning with the right technology partner, you can turn market challenges into your competitive advantage.

Looking for a partner to help you compete?Explore our range of high-performance cutting solutions designed to give you the edge.

Frequently Asked Questions (FAQ)

Q: What is the biggest trend in the foam cutting market right now?

A: Automation and Digitalization. The shift from manual or semi-auto machines to fully automated CNC systems with "nesting" software (to save material) is the dominant trend.

Q: How do I choose between a cheap machine and a premium one?

A: Calculate the Total Cost of Ownership (TCO). A cheaper machine might cost you more in the long run due to frequent repairs, slower cutting speeds, and higher material waste.

Q: Which industries are driving the demand for foam cutters?

A: The e-commerce packaging industry (logistics), the construction industry (insulation), and the automotive industry (interiors) are the top three drivers of demand.