As the global manufacturing landscape evolves, the demand for precision, speed, and versatility has never been higher. The foam cutting machine market is witnessing a significant surge, driven by the expanding needs of the packaging, construction, and automotive sectors.

For manufacturers, staying competitive means more than just owning machinery; it requires understanding where the industry is heading. This article analyzes current market trends, technological innovations, and the future trajectory of foam processing, helping you seize opportunities in a rapidly changing environment.

1. Current Market Trends: What is Driving Growth?

The foam cutting industry is not growing in isolation; it is a direct response to broader global economic shifts.

1.1 Key Growth Drivers

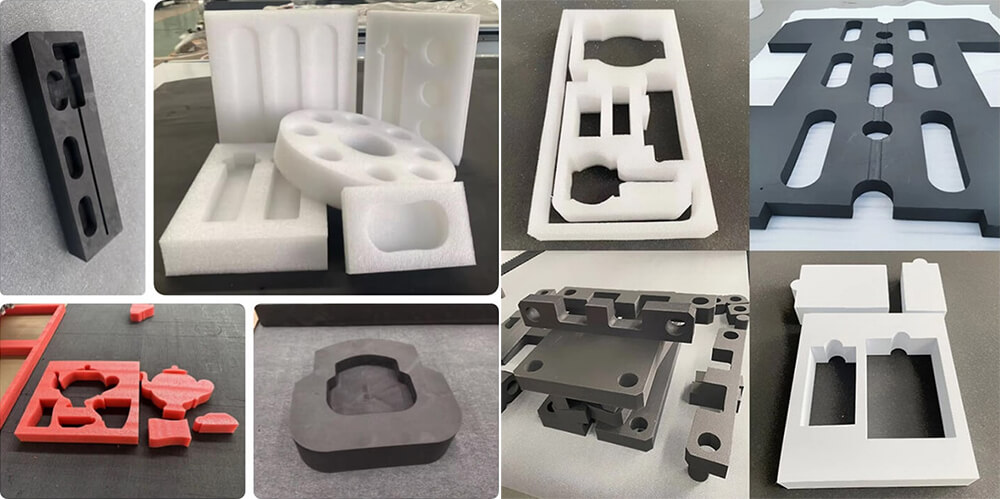

Three major sectors are fueling the demand for advanced cutting solutions:

E-commerce Packaging: The boom in online shopping has created a massive need for protective foam inserts (EPE, PU), requiring machines that can handle high volumes rapidly.

Green Construction: With stricter energy efficiency standards, the demand for thermal insulation materials (XPS, EPS) in construction is rising, necessitating precise cutting for seamless installation.

Automotive Lightweighting: As electric vehicles (EVs) prioritize weight reduction, the use of specialized foam for acoustics and seating is increasing.

1.2 The Shift to Digital Control (CNC)

Manual cutting is becoming obsolete. The market is aggressively shifting toward Computer Numerical Control (CNC). Digitalization ensures that complex geometries can be cut with consistent accuracy, reducing the reliance on skilled manual labor and minimizing human error.

1.3 Impact of Environmental Regulations

Global environmental regulations are tightening. Manufacturers are now looking for machines that generate less waste (dust-free cutting) and can process eco-friendly, recyclable foam materials efficiently.

![Foam Cutting Machine Market Trends & Future Development: Seizing Industry Opportunities Foam Cutting Machine Market Trends & Future Development: Seizing Industry Opportunities]()

2. Technological Innovation: The Core of Competitiveness

To meet these market demands, foam cutting machines are undergoing a technological revolution.

2.1 Automation and Intelligence

Automation is the new standard. Modern cutters now feature:

Auto-Loading/Unloading: Integrating with conveyor systems to create fully automated production lines.

Intelligent Nesting: Software that automatically arranges parts to minimize scrap, directly improving the bottom line.

2.2 Adapting to New Materials

Foam materials are becoming more advanced—denser, more heat-resistant, or composite-based. The latest cutting heads (such as high-frequency oscillating knives and routing spindles) are designed to process these new materials without fusing edges or causing deformation.

2.3 Data Analytics and Monitoring

Industry 4.0 has arrived in foam processing. Advanced machines now offer real-time data monitoring. Operators can track cutting speeds, blade wear, and daily output, allowing for predictive maintenance and data-driven optimization of production workflows.

3. Future Development Directions

Where is the technology heading next? Here is what to expect in the coming years.

3.1 Personalized Customization

The era of mass production is blending with mass customization. The future belongs to flexible machines that can switch from cutting 1,000 identical units to a single custom prototype in seconds. This flexibility allows businesses to take on diverse orders without downtime.

3.2 Cross-Industry Applications

Foam cutting is expanding into high-tech fields.

Electronics: Precision cutting for anti-static foam in microchip transport.

Aerospace: Lightweight core materials for aircraft interiors.

Medical: Specialized foam for orthopedics and medical device packaging.

3.3 Sustainability and Green Manufacturing

Future machine designs will prioritize energy efficiency. We expect to see "greener" machines that consume less power and feature integrated dust extraction systems to ensure a cleaner, safer working environment, aligning with global sustainability goals.

![foam-sheet-cutting-machine foam-sheet-cutting-machine]()

Conclusion

The foam cutting machine market is in a phase of rapid expansion and technological upgrade. From intelligent automation to sustainable practices, the trends are clear: efficiency, precision, and adaptability are king.

To seize these industry opportunities, businesses must invest in equipment that is future-ready. By upgrading to the latest foam cutting technology, you position your company to meet evolving customer demands and stay ahead of the competition.

Ready to future-proof your production line?Contact us today to discuss how our advanced cutting solutions can align with your business goals.

Frequently Asked Questions (FAQ)

Q: Why is the demand for CNC foam cutting machines increasing?

A: The demand is driven by the need for higher precision, faster production speeds in e-commerce packaging, and the requirement for complex shapes in automotive and construction industries that manual cutting cannot achieve.

Q: How does automation in foam cutting reduce costs?

A: Automation reduces labor costs by minimizing manual handling. Furthermore, intelligent nesting software optimizes material usage, significantly reducing waste and raw material expenses.

Q: Can modern foam cutters handle eco-friendly materials?

A: Yes. Modern oscillating knife cutters are specifically designed to handle a wide range of materials, including recyclable and biodegradable foams, without producing harmful smoke or dust.