The manufacturing sector is not static; it is a living, breathing entity that evolves rapidly. As demand for high-performance sealing solutions grows in automotive, aerospace, and electronics, the CNC Gasket Cutting Machine market is expanding alongside it.

For business owners and procurement managers, this growth presents a challenge: How do you invest in machinery today that will still be competitive five years from now? This guide analyzes current market trends—from automation to sustainability—and explains how to choose equipment that positions your business for long-term success.

1. Current Market Trends: Growth and Competition

Understanding the macro environment is the first step in making a smart purchase.

1.1 Market Scale and Growth

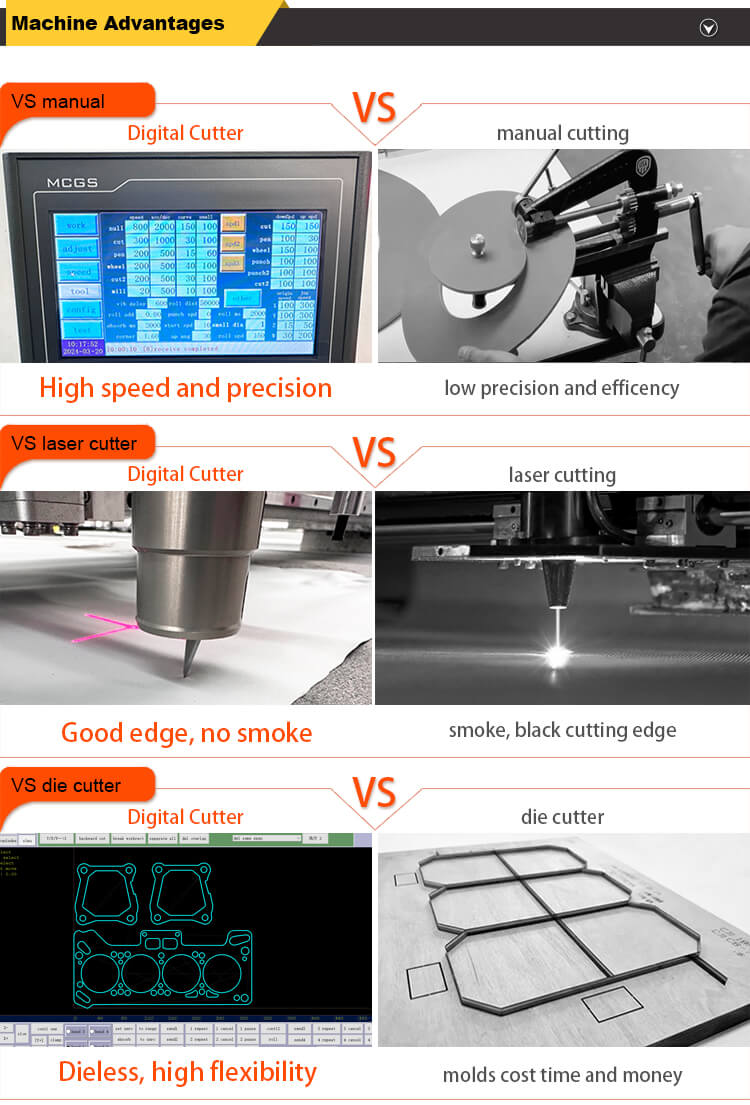

The global gasket cutting market is witnessing a significant shift from manual die-cutting to digital CNC solutions.

The Trend: Manufacturers are moving away from rigid, tooling-heavy processes toward flexible, digital workflows.

Buyer's Takeaway: When choosing a machine, prioritize digital flexibility. Equipment that relies solely on physical dies is becoming obsolete for modern, low-volume/high-mix production orders.

1.2 The Competitive Landscape

The market is dividing into two camps: traditional low-tech cutters and high-tech smart systems.

The Trend: Leading market players are integrating more software capabilities into their hardware.

Buyer's Takeaway: Don't just compare hardware specs. Look for a partner like SL CNC CUT that offers robust software integration, as software is now the primary driver of competitive advantage.

![How to Choose the Best CNC Gasket Cutting Machine for the Future: A Complete Buyer's Guide to Market Trends How to Choose the Best CNC Gasket Cutting Machine for the Future: A Complete Buyer's Guide to Market Trends]()

2. Technical Innovations Driving the Industry

To choose the best machine, you must look for these three key technological features.

2.1 Automation and Intelligence (Industry 4.0)

Labor costs are rising, and skilled operators are hard to find.

Innovation: Modern CNC Gasket Cutting Machines now feature automatic loading/unloading systems and AI-driven vision systems.

Why Choose This: Automated systems reduce human error and drastically lowering your cost per unit.

2.2 Handling New Materials

Gasket materials are becoming more advanced—and harder to cut.

Innovation: New composite materials, high-temp graphites, and memory foams require specialized tool heads.

Why Choose This: Ensure your machine supports interchangeable tool heads. A static machine limits your ability to bid on contracts involving new, exotic materials.

2.3 Data Analysis and Monitoring

You can't improve what you don't measure.

Innovation: Advanced controllers provide real-time production data and can automatically detect the machine's operating status..

Why Choose This: Choose a machine that provides data transparency. This allows you to optimize workflows and predict maintenance needs before a breakdown occurs.

![How to Choose the Best CNC Gasket Cutting Machine for the Future: A Complete Buyer's Guide to Market Trends How to Choose the Best CNC Gasket Cutting Machine for the Future: A Complete Buyer's Guide to Market Trends]()

3. Future Directions: Where is the Industry Going?

Your investment should align with where the world is heading.

3.1 The Rise of Personalized Customization

The era of mass production is being supplemented by mass customization.

The Future: Clients want smaller batches of custom-designed gaskets delivered instantly.

Strategy: A digital cutter with zero wait time is essential. If you need to order a mold for every custom job, you will lose these fast-paced clients.

3.2 Cross-Industry Applications

Gaskets are everywhere.

The Future: We are seeing a surge in demand from the medical device and wearable electronics sectors.

Strategy: Choose a machine with high precision. This capability allows you to pivot your business from heavy industrial gaskets to delicate medical seals if the market shifts.

3.3 Sustainability and Green Manufacturing

Eco-friendly production is no longer optional; it is a requirement.

The Future: Regulations on material waste are tightening.

Strategy: Invest in machines with AI Nesting Software. By maximizing material yield, you not only save money but also position your company as a sustainable supplier—a key selling point for global brands.

Conclusion

The market for CNC Gasket Cutting Machines is evolving towards intelligence, flexibility, and sustainability. To choose the best machine, look beyond the price tag. Look for automation capabilities, data integration, and the versatility to handle tomorrow's materials.

By aligning your equipment choice with these industry trends, you are not just buying a machine; you are securing your company's future in a competitive global market.

Ready to future-proof your production line?Contact our experts to learn about our latest smart cutting solutions designed for the next generation of manufacturing.

Frequently Asked Questions (FAQ)

Q: Is it worth investing in automation for a small shop?

A: Yes. While the initial cost is higher, automation (like auto-feeding) allows a single operator to manage multiple machines. This multiplies your productivity without increasing your payroll, offering a high ROI even for smaller businesses.

Q: What is the environmental impact of digital cutting?

A: Digital cutting is significantly greener than traditional methods. Intelligent nesting software reduces raw material waste by 15-20%, and the electric oscillating process consumes less energy than heavy hydraulic presses.