If you’re sourcing gaskets for automotive, HVAC, oil & gas, or electronics—and you’re still relying on steel dies, waterjets, or outsourced cutting—you’re likely paying more, waiting longer, and sacrificing flexibility.

A CNC gasket cutting machine changes that. It’s a computer-controlled digital cutter that turns CAD files into precise, repeatable gaskets—fast, without hard tooling, and with minimal waste.

I’m Win Zhang, CEO of Jinan Shilai Technology. Since 2010, we’ve helped hundreds of manufacturers bring gasket production in-house using CNC digital knife systems. This guide cuts through the jargon and gives you what you actually need to know in 2025—whether you’re evaluating your first machine or optimizing an existing line.

Who Should Read This?

✅ First-time buyers comparing manual die cutting, laser, waterjet, and digital knife systems

✅ Production managers tired of long lead times, inconsistent quality, or high scrap rates

✅ SMEs and job shops looking to control costs, protect IP, and respond faster to customer changes

If any of that sounds familiar, keep reading.

So… What Is a CNC Gasket Cutting Machine?

At its core, it’s a precision motion system guided by software that drives a cutting tool (usually an oscillating knife) across a flat bed to cut gasket profiles from sheet or roll material—no dies, no heat, no water.

Key Components

Component | What It Does | Why It Matters |

Cutting Table | Fixed or conveyor-style bed with vacuum zones | Holds material flat for accuracy; conveyor enables roll-to-roll cutting |

Tool Head | Oscillating knife (most common), plus optional drag knife, punch, creasing wheel, or marking pen | Handles through-cuts, kiss-cuts, scoring, and part labeling |

Motion System | Servo motors + linear guides + ball screws or rack-and-pinion | Delivers speed, smoothness, and repeatability |

Vacuum System | Suction through perforated table or conveyor belt | Prevents material shift—critical for tight tolerances |

Controller & Software | Imports CAD, auto-nests parts, generates toolpaths | Turns design into production in minutes |

Typical Workflow

Import CAD file (DXF, DWG, AI, etc.)

Auto-nest parts to maximize material use

Load sheet or roll onto table

Engage vacuum hold-down

Select tool profile and cut parameters

Press start → machine cuts unattended

Offload, inspect, and ship—or send data to MES/ERP

![automatic CNC gasket cutting machine (5) automatic CNC gasket cutting machine (5)]()

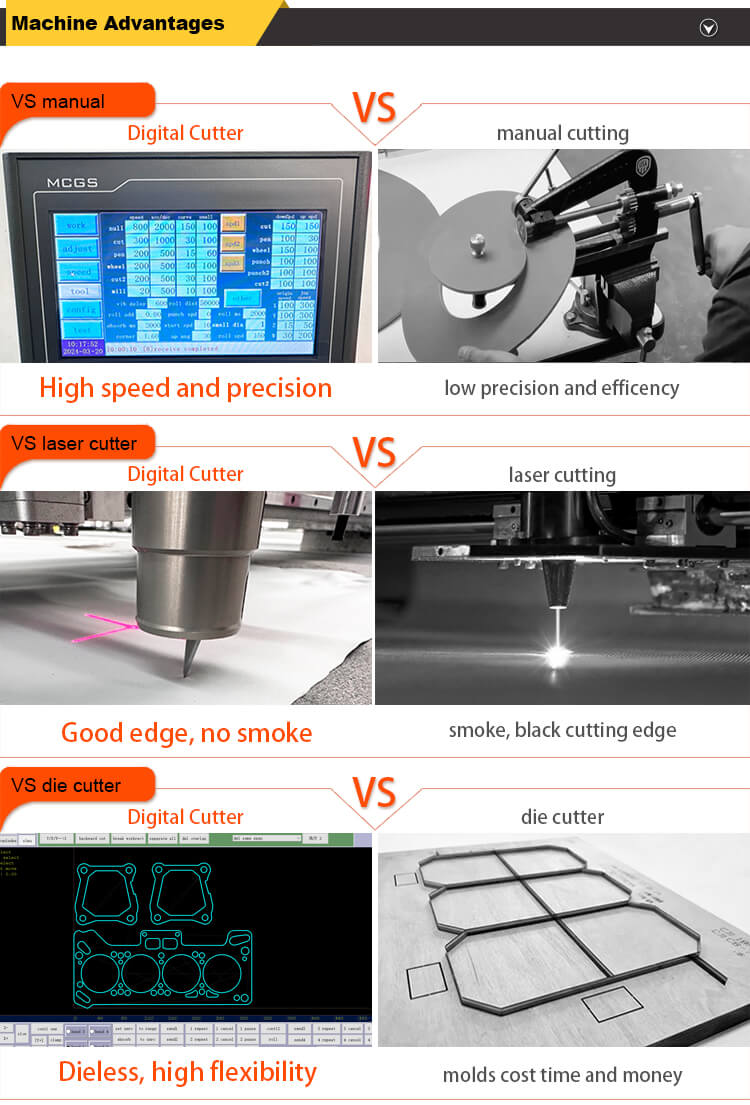

Why CNC Knife Cutting Beats Traditional Methods

vs. Steel Rule Dies

No tooling cost or 2–4 week lead time

Perfect for prototypes, short runs, and frequent design changes

5–12% higher material yield thanks to intelligent nesting

Cleaner cuts on soft foams and elastomers—no crushing or deformation

vs. Laser

Zero heat-affected zone (HAZ) → no charring, hardening, or melted edges on rubber, PTFE, or foam

Safe for adhesive-backed (PSA) materials—lasers often burn the glue

Lower operating cost, no fume extraction needed for most materials

vs. Waterjet

No water saturation—ideal for porous foams and PSA liners

Faster on thin-to-medium soft materials (up. to 3x speed on 3mm EPDM)

Simpler maintenance: no pumps, abrasives, or slurry cleanup

Quieter, cleaner shop floor

![automatic CNC gasket cutting machine (4) automatic CNC gasket cutting machine (4)]()

What Materials Can It Cut?

CNC gasket cutters excel on soft to semi-rigid sheet materials, including:

Elastomers: NBR, EPDM, Silicone, FKM (Viton), CR, SBR

Foams: PU, PE, EVA, EPE, sponge rubber, felt, cork

Engineering Sheets: PTFE (Teflon), flexible graphite (with or without wire mesh), aramid fiber (non-asbestos), gasket paper

Laminates: Adhesive-backed composites, cloth-inserted rubber, fiber-reinforced sheets

Typical thickness range:

Machine Types You’ll See in 2025

1. Fixed-Table Cutter

Best for sheet-based production (e.g., 1m × 2m rubber sheets)

High precision, compact footprint

Ideal for high-mix, low-to-medium volume shops

2. Conveyor (Roll-Fed) Cutter

Cuts directly from rolls—perfect for long gaskets, HVAC seals, or continuous production

Often paired with auto-unwinders, edge guides, and label applicators

3. Multi-Tool Head Systems

Combine oscillating knife + drag knife + punch + ink marker

Enables kiss-cutting (for peelable PSA gaskets), through-cutting, part marking, and micro-tabs—all in one pass

Specs That Actually Matter (Not Just Marketing Numbers)

Spec | What to Look For | Why It Counts |

Cutting Area | Match to your largest sheet or roll width (e.g., 1600×2500 mm) | Avoids wasted space or part truncation |

Max Speed | Up to 1500 mm/s travel—but real cut speed depends on material & geometry | Complex nests benefit more from acceleration than top speed |

Tool Force & Frequency | Adjustable oscillation (e.g., 0–12,000 rpm, 0–20N force) | Critical for cutting dense graphite vs. soft foam |

Vacuum Zoning | 4–16+ independently controlled zones | Holds small parts securely without wasting suction |

Vision System | Optional camera for printed liner registration | Compensates for print-to-cut misalignment |

Accuracy | ±0.1–0.2 mm repeatability on stable materials | Verify with your own material—soft foams may need ±0.3 mm tolerance |

Software | Advanced nesting, kerf compensation, bridge tabs, corner control | Directly impacts yield and edge quality |

Key Capabilities for Real Gasket Production

Through-cut & Kiss-cut: Cut gasket profiles while leaving PSA backing intact

Micro-tabs (bridges): Keep small gaskets attached for easy handling and sorting

Scoring/Creasing: Create fold lines in multi-layer laminates

Part Marking: Ink or etch batch codes, material IDs, or QR codes for traceability

Toolpath Optimization: Smooth corners, control overcuts, prevent lifting on sharp turns

Quality, Tolerances & QA

Typical tolerance: ±0.2 mm on rubber/graphite; ±0.3–0.5 mm on very soft foams

Edge quality: Clean, no burn, no fraying—if you use the right blade

QA best practices:

First-article inspection with go/no-go gauges or CMM

SPC sampling using digital calipers

Barcode/QR labeling tied to job data

Productivity & ROI: What to Expect

Benefit | Impact |

Material savings | 5–12% more parts per sheet vs. manual layout |

Labor efficiency | 1 operator can run 1–2 machines (depending on offload) |

Lead time | From CAD to finished gasket in under 30 minutes |

Maintenance cost | Blades, felt underlay, vacuum filters—no high-cost consumables |

Payback period | Typically 6–18 months when replacing outsourcing or inefficient methods |

Blades, Consumables & Maintenance

Blades: Match to material—fine edge for rubber/PTFE, coarse tooth for thick foam, coated for abrasive fibers

Felt underlay: Protects the table and improves cut finish; rotate weekly, replace monthly

Vacuum filters/seals: Clean weekly; replace when suction drops

Simple Maintenance Schedule

Daily: Wipe table, inspect blade, check vacuum

Weekly: Tighten fasteners, inspect rails, clean filters

Monthly: Lubricate per spec, recalibrate, back up software configs

Safety & Environmental Notes

No open flame or high heat → minimal fumes on most materials

Dust control: Use local extraction when cutting graphite or aramid fibers

Noise: Oscillating head produces mechanical noise—consider enclosures in shared spaces

ESD: Anti-static measures help with PSA liner handling and reduce debris cling

Software: The Brains Behind the Cuts

File support: DXF, DWG, AI, PLT (most common); some support STEP → 2D conversion

Nesting intelligence: Respects grain direction, minimizes spacing, handles kiss-cut depth rules

Production integration: Export job reports, material yield, blade usage; connect to MES/ERP

Your 2025 Buying Checklist

Before you talk to a vendor, ask:

What are my largest and smallest gasket dimensions?

What materials and thicknesses do I cut most? (Include PSA?)

Am I doing prototypes, short runs, or high-volume roll production?

Do I need kiss-cutting, marking, or vision alignment?

What table size and vacuum zoning match my part mix?

What’s the service response time? Are spare parts local?

Can I test with my own material and CAD file? (Insist on this!)

What’s the total cost of ownership—not just the purchase price?

Common Pitfalls (And How to Avoid Them)

Using laser on rubber or PSA → Burnt edges, failed seals

✅ Use oscillating knife instead

Weak vacuum on small gaskets → Parts shift, tolerances drift

✅ Add more vacuum zones or use a carrier sheet

Ignoring kerf compensation → ID too tight, OD too big

✅ Calibrate per material—don’t guess

Skipping config backups before updates → Lost tool libraries, rework

✅ Back up to USB + cloud before every firmware change

Over-greasing rails → Dust sticks, accelerates wear

✅ Apply thin, clean lubricant per manufacturer spec

Real Results You Can Count On

Same-day prototyping: Design in the morning, ship parts by afternoon

Higher yield: Save thousands on expensive PTFE or graphite sheets

Consistent quality: Same cut on shift 1, shift 3, and next month

Agile production: Switch jobs in minutes—not days

About Jinan Shilai

We design and build CNC digital cutting systems for gasket, foam, and composite applications—with fixed or conveyor tables, multi-tool heads, vision alignment, and open software that works with your existing workflow.

Want proof it works for your material?

Send us your CAD file and material specs. We’ll cut samples, share video, provide measurement reports, and give you a realistic ROI estimate—no sales pitch.

Get Your Free Sample Cut & ROI Analysis

Win Zhang | CEO, Jinan Shilai Technology Co., Ltd.

Helping manufacturers cut smarter—not harder—since 2010.