Short answer: Oscillating knife CNC cutting eliminates hard tooling, slashes lead times, boosts material yield, and delivers clean, precise edges—without heat, water, or waste. It’s turning gasket production from a slow, die-dependent process into a fast, flexible, digital operation.

If you’re still using dies to cut gaskets in 2025, you’re working harder—and spending more—than you need to.

From Dies to Digits: The Real Shift in Gasket Manufacturing

The old way:

Steel rule dies. Punch presses. Weeks of lead time. Expensive retooling every time a flange changes or a tolerance tightens. Inventory piling up “just in case.”

The new reality:

Upload a CAD file. Let the software nest the parts. Press start. Walk away.

No dies. No storage racks. No approval cycles. Just gaskets—cut accurately, on demand.

This isn’t just incremental improvement. It’s a fundamental shift from analog tooling to digital manufacturing—and it’s giving agile shops a serious edge.

![automatic CNC gasket cutting machine (5) automatic CNC gasket cutting machine (5)]()

What Exactly Is Oscillating Knife Cutting?

At its heart, it’s cold, mechanical cutting guided by software.

A high-speed motor drives a blade in a rapid up-and-down motion (oscillation)—typically 6,000 to 12,000 cycles per minute—while the tool head moves precisely across the material. The result? Clean, controlled cuts through soft and semi-rigid sheets, with no burning, no water, and minimal deformation.

A typical system includes:

A vacuum table (fixed or conveyor-fed) to hold material flat

A multi-tool head with oscillating knife, drag knife, micro-punch, and marking pen

Optional vision camera for printed liner alignment

Nesting software that turns DXF files into optimized cutting paths

The key advantage? It cuts like a scalpel—not a stamp.

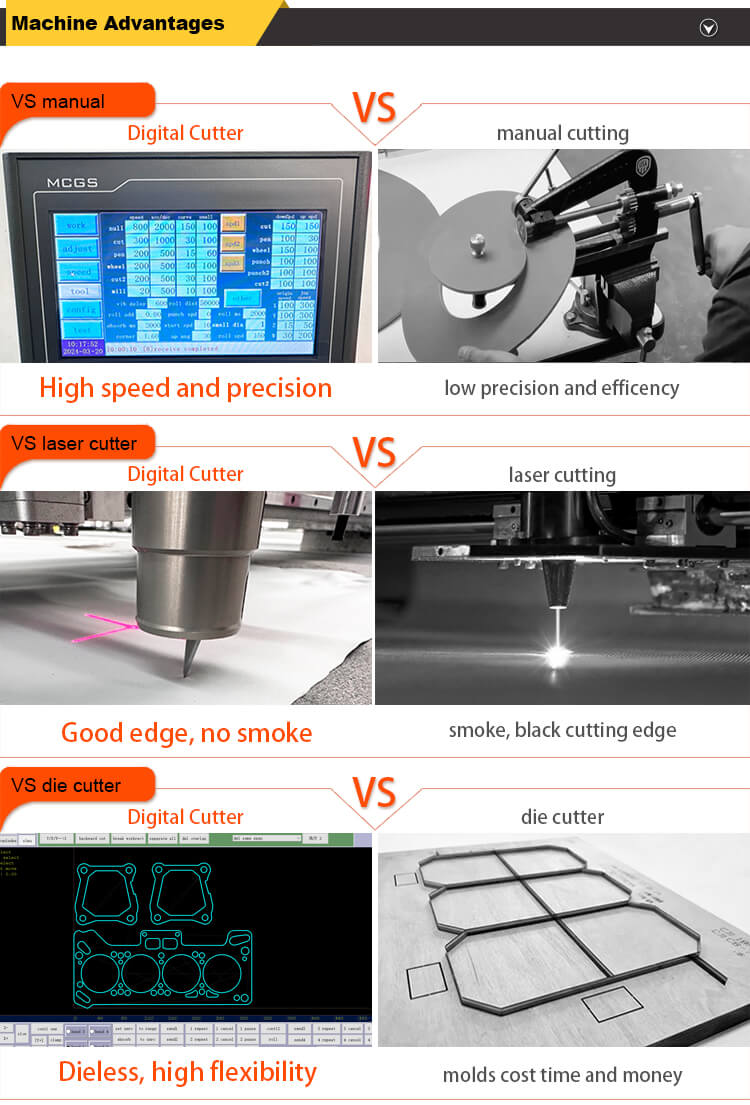

Die Cutting vs. Oscillating Knife: Why the Difference Matters

Factor | Steel Rule Die | Oscillating Knife CNC |

Tooling | $500–$5,000 per die; 1–4 week lead time | $0 tooling cost; change jobs in minutes |

Design changes | Requires new die, budget approval, downtime | Update CAD file → cut new version same day |

Material yield | Fixed layout; manual nesting; 5–10% waste common | Algorithmic nesting; 5–12% higher yield on average |

Edge quality | Compression can crush foams or distort rubber | Clean shear with minimal burr—especially on PSA materials |

Total cost | Dies wear out, break, get lost; storage adds overhead | Consumables: blades, felt underlay, filters—predictable OPEX |

For high-mix, low-volume, or fast-iteration environments, the math is clear.

![automatic CNC gasket cutting machine (4) automatic CNC gasket cutting machine (4)]()

Why Knife Cutting Beats Laser and Waterjet for Gaskets

vs. Laser

No heat-affected zone (HAZ) → no charring on EPDM, no melted edges on PTFE

Preserves adhesive integrity on PSA-backed foams—lasers often burn the glue layer

Safer for elastomers that off-gas toxic fumes when burned

vs. Waterjet

No water absorption → critical for porous foams, fiber sheets, and paper-based gaskets

No delamination of laminated or mesh-reinforced materials

Lower operating cost: no abrasives, no slurry disposal, no drying time

Cleaner shop floor—no wet mess, no corrosion risk

For gasket materials—especially soft, heat-sensitive, or adhesive-backed ones—mechanical knife cutting is simply the right physics for the job.

Materials That Shine with Oscillating Knife Cutting

Modern systems handle a wide range of sealing media:

Elastomers: NBR, EPDM, Silicone, FKM (Viton), CR, SBR

Foams & soft media: PU, PE, EVA, EPE, sponge rubber, felt, cork

Engineering sheets: PTFE, flexible graphite (with/without wire mesh), aramid fiber (non-asbestos), gasket paper

Laminates & PSA stacks: Kiss-cut cleanly through top layers without piercing the liner

Typical thickness range: 0.2 mm to 30 mm in a single pass—depending on blade type and material density.

Precision You Can Trust

For flange gaskets, battery seals, or EMI shielding, this level of control ensures first-time-right parts—shift after shift.

The Real ROI: Productivity Gains That Add Up

Lead time: From CAD to finished gasket in under 30 minutes

Throughput: High acceleration + smart toolpaths = faster cycles on complex nests

Labor: One operator can run multiple jobs with auto-nesting and labeling

Payback: Most shops see ROI in 6–18 months by eliminating die costs and reducing scrap

One automotive supplier cut $120,000/year in die expenses and reduced prototype lead time from 10 days to 2 hours.

What’s New in 2025 Systems?

Today’s machines aren’t just “CNC cutters”—they’re integrated production cells:

Smart tool heads: Adjustable oscillation frequency and force; quick-swap cartridges

Adaptive vacuum zoning: Focus suction on small parts or narrow webs

Vision + AI: Cameras detect fiducials or printed edges; software auto-adjusts for material stretch

Open software: Nesting with grain rules, kiss-cut depth libraries, and direct ERP/MES integration

These aren’t lab curiosities—they’re shop-floor tools built for real-world production.

Real Wins Across Industries

Automotive/EV: Same-day iteration on battery pack seals in FKM and silicone

HVAC: High-mix foam gaskets with kiss-cut PSA liners—cut from roll, labeled, ready to ship

Oil & Gas: Clean, traceable cuts on graphite/PTFE composites with QR-coded part marking

Electronics: ESD-safe cutting of conductive foams with tight ID tolerances (<±0.15 mm)

The common thread? Speed, flexibility, and zero tooling dependency.

Your 2025 Implementation Roadmap

Map your parts: Max/min dimensions, tightest tolerances, PSA usage, smallest holes

Choose table type: Fixed for precision sheets; conveyor for roll-fed high volume

Select tooling: Oscillating knife + drag knife + punch + marker (add camera if using printed liners)

Run trials: Cut your material with your CAD—verify edge quality, speed, and accuracy

Plan data flow: Standardize CAD layers, nesting rules, label formats, and job tracking

Train your team: Operators, maintenance, and engineering—everyone needs a role

Pro tip: Never buy without a live demo on your material. If the vendor won’t cut your sample, walk away.

Maintenance That Keeps You Cutting

Daily: Clear debris, inspect blade, check vacuum suction

Weekly: Tighten fasteners, clean filters, inspect rails

Monthly: Lubricate per manual, recalibrate, back up software configs

Blade strategy:

Fine-edge blades for rubber, PTFE, graphite

Coarse-tooth for thick foams

Coated blades for abrasive fibers

A well-maintained system runs for years with minimal downtime.

Common Mistakes (And How to Avoid Them)

❌ Assuming “CNC = automatic perfection”

→ You still need to set kerf, corner rules, and vacuum zones per material.

❌ Running tiny gaskets on a single vacuum zone

→ Use micro-tabs, carrier sheets, or multi-zone vacuum to hold small parts.

❌ Over-greasing linear rails

→ Attracts dust and grime. Use thin, clean lubricant—only where specified.

❌ Updating firmware without backing up

→ Always save tool libraries and machine configs before any software change.

The Bigger Picture: From Cost Center to Competitive Advantage

Companies adopting oscillating knife cutting aren’t just saving money—they’re transforming how they operate:

Faster product launches: Engineering changes go straight to the floor

Leaner inventory: Produce to order, not to forecast

Consistent quality: Digital recipes eliminate operator-dependent variation

Sustainability wins: Less scrap, no toxic fumes, no wastewater

In short: you’re not just cutting gaskets. You’re cutting lead time, waste, and risk.

About Us

At Jinan Shilai Technology, we build CNC digital cutting systems engineered specifically for gasket, foam, and composite materials. Our machines combine fixed or conveyor tables, multi-tool heads, vision alignment, and open software—so you can move from die-bound to fully digital, fast.

Want to see it with your own eyes?

Send us your material sample and CAD file. We’ll cut it, measure it, film it, and send you a full report—including a realistic ROI estimate for your operation.

Request Your Free Sample Cut & ROI Analysis