Hi, I’m Win Zhang, CEO of Jinan Shilai Technology — a leading digital cutter manufacturer right here in China. For years, I’ve sat across from gasket makers, listening to their biggest frustrations. And one complaint comes up more than any other: die-cutting.

Let’s be real — nobody gets excited about waiting weeks for a new die mold, only to open the box and realize it doesn’t fit your latest gasket design. Traditional die-cutting used to be the go-to for sealing parts, but let’s face it: times have changed.

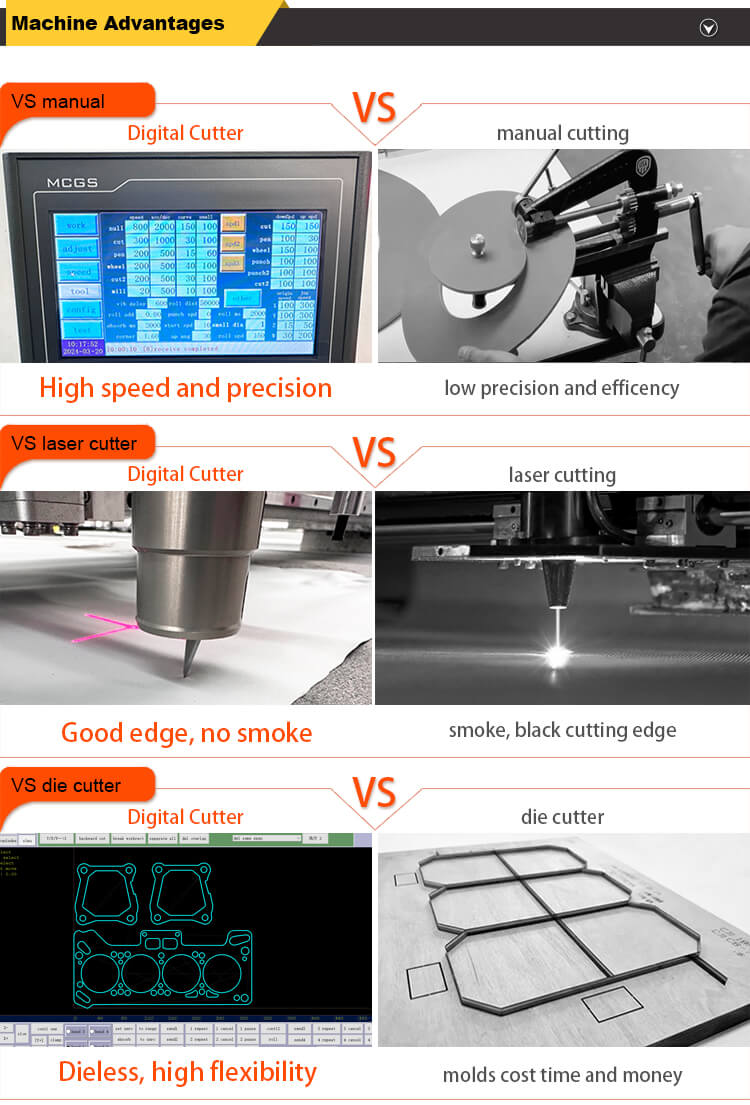

Today, CNC oscillating knife cutters (our specialty at Shilai) are taking over the rubber gasket world. They’re faster. They’re cheaper. And whether you need 10 gaskets or 10,000, they handle it without breaking a sweat.

I want to walk you through exactly why this shift is happening — no jargon, just real talk about speed, flexibility, cost, and stories from my actual customers. By the end, you’ll see why die-cutting is slowly but surely heading toward “retirement” for most gasket shops.

First, let’s call out the elephant in the room: Traditional die-cutting’s pain points

Die-cutting is basically like using a giant cookie cutter for gaskets. You make a steel mold, slap it in a press, and stamp out the same shape over and over. Sounds simple enough, right? But here’s where it falls apart — and where my customers used to pull their hair out:

Every new design = a new mold: Want to tweak a gasket’s size or add a hole? You can’t just adjust the press — you need an entirely new steel die.

Molds are expensive: A basic die might set you back \(300, but complex shapes? We’re talking \)1,000 or more. Multiply that by 5 or 10 designs a year, and it adds up fast.

Wait times kill momentum: Getting a mold made takes days — sometimes weeks. If a customer needs gaskets in a hurry? You’re stuck saying, “Sorry, we’re waiting on the die.”

Molds wear out: After hundreds (or thousands) of stamps, the die gets dull. Then you’re back to ordering a new one — more cost, more waiting.

![automatic CNC gasket cutting machine (4) automatic CNC gasket cutting machine (4)]()

Don’t get me wrong: For huge batches of super simple shapes (think 100,000 identical gaskets), die-cutting used to make sense. But when customers started asking for custom designs, small runs, or last-minute tweaks? The whole system collapsed.

Let me break it down with a quick comparison — the numbers speak for themselves:

Feature | Traditional Die-Cutting | CNC Rubber Gasket Cutting |

Setup Cost | High (molds = \(300–\)1,000+) | Zero (just upload a CAD file) |

Lead Time | Days to weeks | Minutes |

Flexibility | One mold = one shape | Unlimited shapes (swap files!) |

Maintenance | Mold sharpening/replacement | Cheap blade changes |

Small-Batch Orders | Expensive (mold cost kills you) | Cost-effective (no mold fees) |

CNC cutting: The modern solution (no molds, no headaches)

Let me paint a better picture: Imagine never waiting for a mold again. You get a customer’s gasket design, upload the CAD file to your machine, and 10 minutes later, you’re holding a perfect cut. That’s what our CNC rubber gasket cutters do — and they’re game-changers.

Here’s why they work so well:

We built tools for your materials

Rubber isn’t one-size-fits-all. Some sheets are thick and dense; others are thin and flexible. Our machines come with different tools to handle it all:

Pneumatic oscillating tools: For thick, tough rubber (think industrial gaskets).

High-frequency oscillating knives: For thin, precise cuts (great for automotive or electronic gaskets).

400W electric oscillating tools: For super-hard materials like PTFE or graphite-reinforced rubber.

One machine, multiple materials — no swapping out expensive dies, just quick tool changes (if you even need them).

Speed: From “weeks” to “same day”

Speed is where CNC really crushes die-cutting. Let me tell you about a U.S. customer of ours: They needed 50 custom rubber gaskets for a prototype. With die-cutting, their supplier quoted 7 days (most of that waiting for the mold). We cut those 50 gaskets on our CNC machine in one hour — including setup.

Let’s map that timeline out so you can see the difference:

Step | Die-Cutting Timeline | CNC Cutting Timeline |

Design Finalization | 1–2 days | 1–2 hours (tweak the CAD file) |

Mold Making | 3–7 days | None (skip this step entirely) |

Cutting Production | 1–2 days | Same day (even hours!) |

Total | 7–14 days | 1 day (max!) |

That’s not just “faster” — that’s a complete shift in how you serve your customers. Instead of saying, “We’ll get back to you in a week,” you can say, “We’ll have it ready tomorrow.”

Flexibility: Say yes to custom orders (no more “sorry”)

How many times have you had a customer ask for a weird-shaped gasket or a one-off design — and had to turn them down because you didn’t want to pay for a new mold?

With CNC, that’s a thing of the past. Want a gasket with a crazy curve? Load the file. Need to adjust the thickness mid-job? Just tweak the settings. One of my favorite stories is about a Canadian sealing company: They used to run two separate die-cutting setups — one for automotive gaskets, one for HVAC parts.

After switching to our CNC machine, they handle both markets with one setup. No mold swapping, no wasted time — just “yes” to every custom request.

And thickness? We’ve cut rubber sheets from 1mm up to 20mm with the same machine. No limits, no excuses.

Cost savings: Keep your money (no more mold bills)

Let’s talk numbers — because I know that’s what matters most to your bottom line.

A typical mold costs \(500 (and that’s on the cheap side). If you make 10 new gasket designs a year, that’s \)5,000 just in molds. With CNC? Mold cost = $0. The only thing you replace is the blade — which costs a few dollars each.

Then there’s material waste. Die-cutting leaves gaps between shapes (you can’t nest them perfectly), so you lose 15% or more of your rubber sheet. Our CNC software auto-nests shapes as tightly as possible — cutting waste down to 5% or less. That’s 10% more material you can actually use (or save money on buying less).

One of our gasket clients saved \(15,000 in mold costs alone in their first year with our CNC machine. Let me repeat that: \)15,000. That’s not pocket change — that’s money you can reinvest in your business, hire more staff, or expand your product line.

Quality: No more jagged edges (or leaky seals)

Rubber gaskets are all about precision. A jagged edge or inconsistent cut can mean a leaky seal — and a very unhappy customer (not to mention costly returns).

Die-cutting struggles here: As molds wear out, they leave rough edges or uneven cuts. CNC oscillating knives? They deliver smooth, burr-free edges every single time. The machine’s computer controls the depth and speed, so every gasket is identical — no mistakes, no reworks.

And if you need half-cuts (for adhesive gaskets) or full through-cuts? You can do both in the same job. No more switching machines or adjusting setups — just push a button.

A real case study: The U.S. manufacturer that doubled their business

Let me share a story that sums up why CNC is the future. A U.S. sealing company came to us frustrated with die-cutting delays. They were losing customers because they couldn’t turn around custom orders fast enough. They bought one of our SHILAI CNC machines, and here’s what happened in a year:

Lead time went from 10 days to 1 day.

They saved $15,000 in mold costs.

They started offering custom one-off gaskets (something they never could before).

Customers began calling them the “fastest gasket shop in town” — and referrals poured in.

They told me, “This machine didn’t just save us money. It got us new business.” That’s the kind of impact we build for at Shilai — not just tools, but growth.

When die-cutting still makes sense (let’s be fair)

I’m not here to bash die-cutting entirely. It still has a place — if you’re making millions of identical, super-simple gaskets every month. When the mold cost spreads out over that much volume, it might be cheaper.

But for 90% of gasket shops? CNC is better. If you do small batches, custom designs, or multiple shapes? CNC wins hands down. That’s why so many of our customers use both: CNC for custom work, die-cutting for high-volume standard parts. It’s the best of both worlds.

Final thought: It’s time to stop waiting on molds

The writing’s on the wall: Rubber gasket cutting machines are replacing traditional die-cutting for good reason. They’re faster, more flexible, cheaper, and deliver better quality. Die-cutting isn’t dead — but it’s no longer the default.

If you’re still waiting weeks for molds, turning down custom orders, or wasting money on die fees and material waste? It’s time to rethink your cutting strategy.

At Shilai, we don’t just sell CNC machines — we solve your problems. We’ll work with you to understand your materials, your volume, and your customers’ needs. And if you’re not sure? Send us a sample of your rubber, and we’ll do a free test cut. We’ll even send you a video of the process so you can see the quality for yourself.

Head over to www.slcnccut.com to learn more, or drop me an email directly. I’m always happy to chat about how CNC can transform your gasket business.

Until then, stop waiting on molds — start cutting faster.

— Win Zhang, CEO, Jinan Shilai Technology Co., Ltd.