Ever found yourself wrestling with oversized carpet rolls, struggling to match intricate printed patterns, or watching your production line crawl under manual cutting methods? I've been there too. As CEO of Jinan Shilai Technology, I've spent years helping carpet manufacturers solve exactly these challenges.

Why Your Current Carpet Cutting Method is Costing You Money

Let's be honest: most carpet cutting setups are holding you back.

The oversized carpet problem: Standard cutting tables can't handle your largest rolls. Constant repositioning? That's lost time and wasted material.

The pattern nightmare: Those busy printed designs? Manual cutting can't keep up with irregular shapes and shifting patterns. One misalignment and you've got scrap.

The manual bottleneck: Die cutting? It's slow, inconsistent, and eats up your labor budget. For every hour spent setting up, you're losing potential production.

The material chaos: Needle-punch, tufted, PVC-backed, felt - each with thicknesses from 0.1mm to 30mm. One machine for all these? That's the dream.

The customization explosion: Customers want custom sizes, special inlays, and branded patterns - yesterday. Manual cutting can't keep up.

The laser trap: Burnt edges, yellowing, and that awful odor? You're not alone. Many carpet manufacturers have ditched lasers for good.

How We Actually Solve These Problems

At Jinan Shilai, we've built CNC carpet cutting machines specifically for these real-world challenges. Here's how we make it work:

Big enough to handle your largest rolls

No more repositioning. Our machines feature customizable work areas that match your actual roll width. Fewer flips. Fewer joins. More yield. Period.

Smart vision that actually works with real carpets

Our large-area CCD system identifies printed outlines and irregular shapes - even when patterns shift slightly. It auto-aligns toolpaths so your cuts stay precise, even with fabric wrinkles.

Pure physical cutting, no heat, no fuss

No burn marks. No yellowing. No odor. Just clean, consistent cuts, batch after batch. That's why we call it "clean cutting" - it's not just marketing.

No dies, no setups, just pure speed

Switch jobs with a click. Compared to manual cutting, most of our customers see 3-5x productivity gains. That's not a theoretical number - it's what we see every day.

Material flexibility you'll actually use

Carpet tiles, broadloom, felt, EVA underlayment, acoustic panels? Swap materials instantly without retooling. Our multi-tool heads handle it all.

CAD workflow that makes customization effortless

Import your CAD files, nest intelligently, and hit go. For custom orders and small batches, this is game-changing.

What Cutting Tools Actually Work Best for Your Carpet

We don't believe in one-size-fits-all. Here's what we recommend:

Oscillating knife: Our go-to for most carpet types and foam underlays. Delivers clean edges without fraying.

Drag knife: Perfect for thin, stable materials when speed is critical.

Rotary tool: Great for certain textiles and layered composites.

Creasing/punch options: Essential for packaging rolled carpets or accessory kits.

Most shops find dual-tool or multi-tool heads become their daily productivity heroes.

Real Questions, Real Answers

"Will your vision system handle my printed patterns?"

Yes. Our CCD system works with real-world conditions - wrinkles, slight print distortions, and batch variations. You get crisp inlays, consistent border trims, and less scrap.

"How fast can I actually cut?"

Setup time drops to minutes. One trained operator can manage multiple machines. With intelligent nesting, you'll squeeze more pieces out of every roll. Most customers see 3-5x the output of manual methods.

"Will it handle my specific material thickness and backing?"

Absolutely. We support 0.1mm to 30mm - covering everything from felt to thick PVC-backed carpets. If you're unsure, we'll run a cutting test on your samples and recommend the perfect tool configuration.

Why This Actually Improves Your Bottom Line

No heat defects: Physical cutting eliminates burn marks and yellowing entirely.

Edge accuracy: Vision alignment keeps patterns perfectly matched.

Repeatable quality: Digital files ensure consistency across orders and locations.

Controlled pressure and speed: Prevents edge fuzzing and delamination.

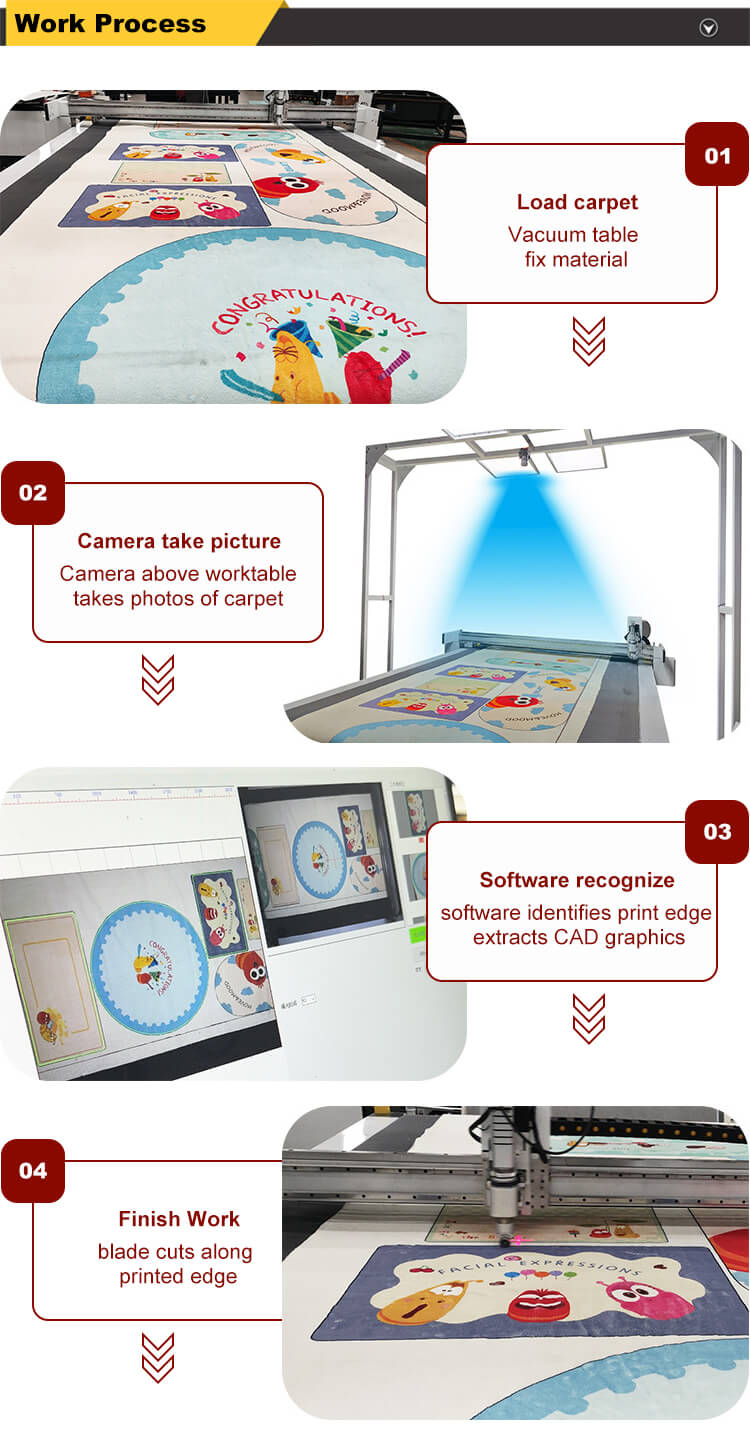

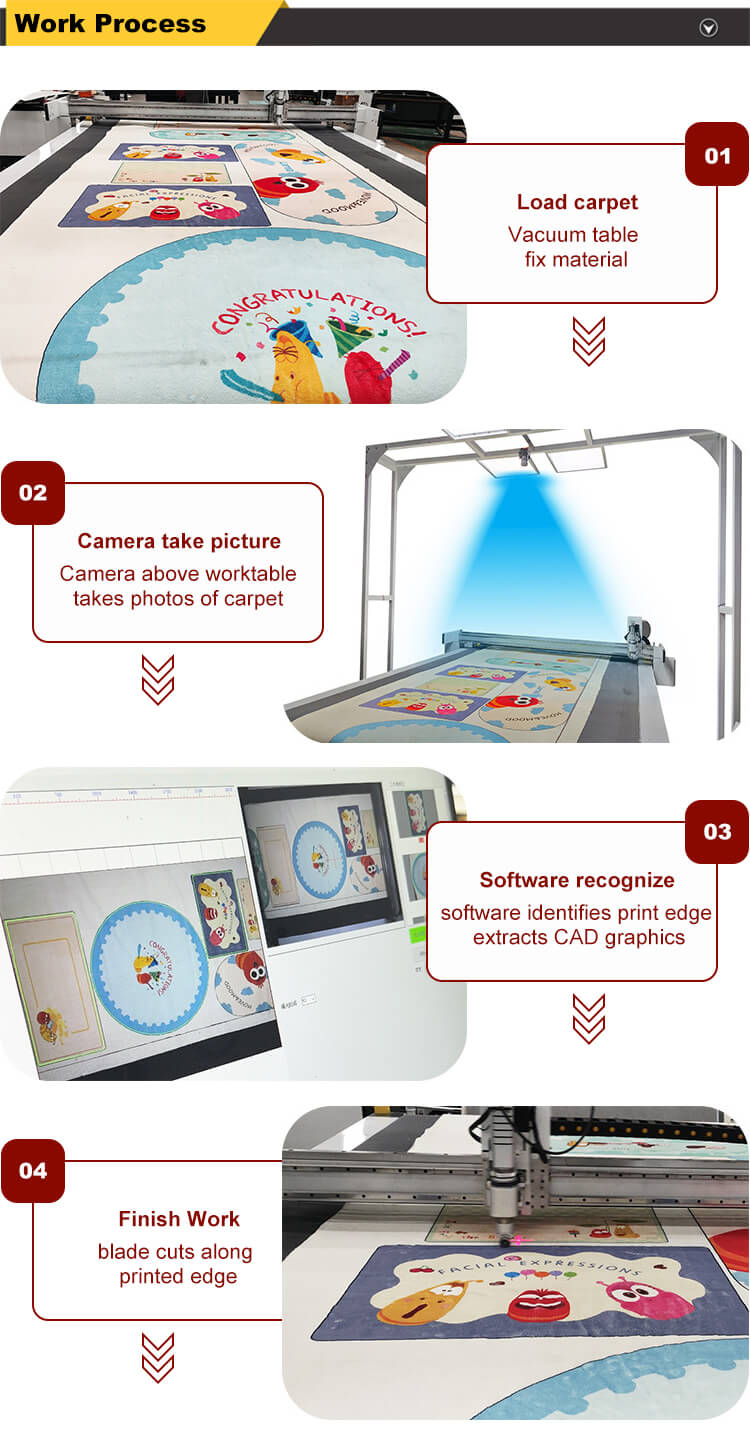

Your Day-to-Day Workflow Just Got Simpler

Import your CAD design

Auto-nest for minimal waste (optional)

Place material, trigger CCD recognition if needed

Select tool profile and start the job

Offload finished pieces - clean edges, ready for binding or installation

Who's Actually Using This Right Now?

Carpet manufacturers and converters handling large-scale production

Custom rug makers delivering high-end, personalized pieces

Event and exhibition contractors needing fast, one-off shapes

Acoustic and insulation product makers with complex material stacks

Automotive, aerospace, and transport interior specialists

Hospitality and retail teams demanding consistent branding

Why Choose Jinan Shilai?

We're not just selling machines. We're solving real problems for real manufacturers.

Large-format tables designed for your actual needs

CCD vision that works with irregular patterns and printed designs

Multi-tool heads optimized for carpet and flexible materials

Clean, physical cutting - no burn, no odor, no deformation

CAD-native workflow for true custom manufacturing

Field-tested reliability with local support and remote diagnostics

Ready to Stop Wasting Time on Carpet Cutting?

Tell us your materials, max roll width, and typical job sizes.

Share your throughput targets and finish quality requirements.

We'll recommend the perfect machine size, tool heads, and workflow software.

We'll even cut your sample files on our machines and send you the results.

Stop wrestling with carpet cutting. Start producing with precision.

See a live demo or request a sample cut - we'll help you spec the right machine for today, and the flexibility you'll need tomorrow.