I’m Win Zhang, CEO of Jinan Shilai Technology Co., Ltd., and I want to share what I’ve learned about why a digital cutting machine for fabric is one of the most practical investments a textile business can make today. We design and build these systems, and over the years I’ve seen small workshops and large manufacturers alike change the way they work once they introduce digital cutting into the workflow.

Why digital cutting matters

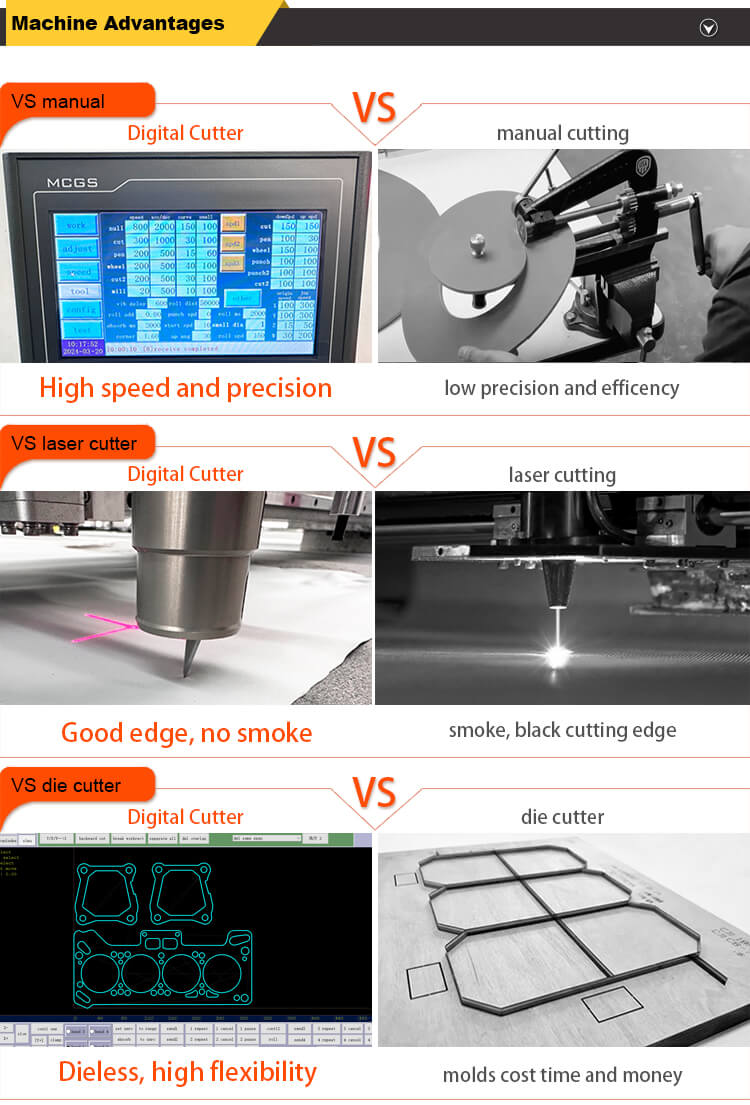

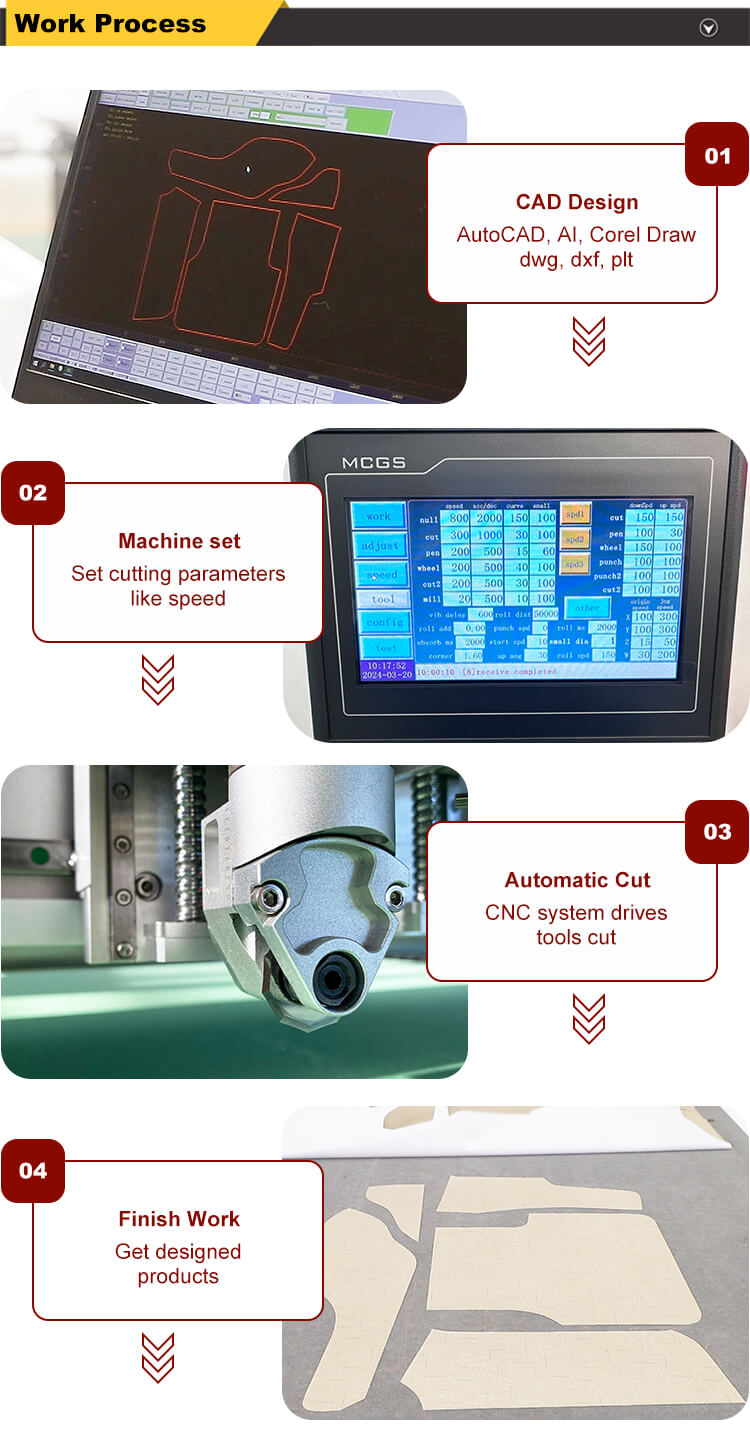

If you cut fabric by hand or with manual die presses, you know the pain points: inconsistent cuts, wasted material, long setup times, and the constant need for skilled operators. A digital cutting machine for fabric removes most of those headaches. It combines CAD/CAM integration, precise toolheads (knives, lasers, oscillating blades), and automated handling so you get consistent parts, faster turnaround, and less waste.

Types of machines and when to use them

Here’s a quick, practical run-down of the main types and where they make sense:

CNC knife cutting machines: Best for general textiles—knits, wovens, leather and some technical fabrics. They use drag, oscillating, or rotary knives and can cut single or multiple layers under numerical control.

Laser cutting machines: Great for delicate fabrics (silk, lace) or designs with intricate detail. Laser cuts can seal edges and reduce fraying.

Die cutting machines: Efficient for high-volume, repeatable shapes—quilting pieces, appliqués, or parts where a custom die makes sense.

Electronic home-craft cutters (e.g., Cricut-style): Ideal for hobbyists and small studios working with thin fabrics and small-batch projects.

![automatic CNC gasket cutting machine (4) automatic CNC gasket cutting machine (4)]()

What I see customers value most

From smaller fashion brands to automotive interior shops, the consistent themes are precision, speed, and reduced material waste.

Precision and repeatability: Digital control means each piece matches the CAD file. That eliminates “good today, bad tomorrow” variability.

Multi-layer throughput: Many of our machines handle 6–20 layers or more in one pass. That can boost cutting throughput by several times compared to manual cutting.

Faster setup and nesting: Importing CAD/PLM files and running nesting algorithms reduces idle time and trims material usage.

Automation: Auto-loading/unloading, vacuum tables, and safety sensors keep machines running longer with less oversight.

![1 (6) 1 (6)]()

Real-world outcomes

You shouldn’t expect change overnight, but you should expect predictable improvements. Typical benefits we see include:

Faster job turnaround because setup is largely digital.

Less fabric waste due to optimized nesting.

Lower dependency on highly trained manual cutters.

Consistent edge quality, which reduces rework in downstream sewing or assembly.

How to choose the right digital cutting machine for fabric

There’s no one-size-fits-all answer. When advising customers I always focus on these practical questions:

What materials will you cut? Knits, wovens, leather, composites, or a mix? Make sure the machine handles your substrates and finishes.

What layer capacity do you need? If your production targets require stacking 10–20 layers, pick a system rated for that.

What speed is realistic for your workflow? Machines can reach high feed rates (some systems approach 48 m/min), but overall throughput depends on loading/unloading, nesting, and downstream processes.

How flexible must tooling be? Ask about interchangeable toolheads—V-cut, kiss-cut, oscillating knives—so you can handle different jobs without a new machine.

What software ecosystem do you want? Good nesting algorithms and easy CAD import are critical. Also think about integration with PLM or ERP systems.

How much automation do you need? Auto-loading, vacuum tables and part dropping can reduce labor and increase uptime—but they add to footprint and cost.

Avoiding common mistakes

From what I’ve learned working with customers, here are three mistakes to avoid:

Buying the fastest machine without matching upstream/downstream processes. Speed matters only if the rest of the line can keep up.

Overlooking software and training. A powerful cutter with poor software or no operator training is an expensive paperweight.

Picking the wrong tooling mix. If you plan to cut varied materials, make sure the vendor supplies or supports the right cutters.

A few trust-building notes about us

As the CEO of Jinan Shilai Technology, I’m proud that we focus on real-world durability and long-term serviceability. We work directly with customers to match machines to production goals and provide training so teams can get the most from their investment. If you’re considering a digital cutting solution, I encourage you to ask about service response times, spare parts availability, and software updates—those things matter a lot over the life of the machine.

If you want to take the next step

If you’re evaluating digital cutting machines for fabric, let’s talk. Tell us about the materials you cut, your layer requirements, and your daily throughput target. We can recommend a solution—CNC knife, laser, or a hybrid—and arrange a demo or factory visit.

Visit our website: www.slcnccut.com/ to see our product range, or contact our sales team through the site to set up a consultation. I’d be happy to walk you through real examples and ROI scenarios based on your specific needs.