Precision Cutting for PP Hollow Sheet

Working with PP hollow sheet presents a unique set of challenges. Manual cutting with a utility knife is slow, inconsistent, and produces rough, unprofessional edges. It’s nearly impossible to create clean, reliable fold lines by hand. While PP hollow sheet is a versatile and cost-effective material, processing it efficiently and professionally requires a specialized solution.

The SL1625HF PP Hollow Flatbed Digital Cutting Machine is engineered specifically for this purpose. It replaces slow manual labor with high-speed, automated precision, allowing you to transform full sheets of Coroplast, Corflute, and other plastic cardboards into perfectly finished products in a single, streamlined process.

Core Advantages: Master Your Material

The SL1625HF is built to handle the unique properties of PP hollow sheet with unmatched precision.

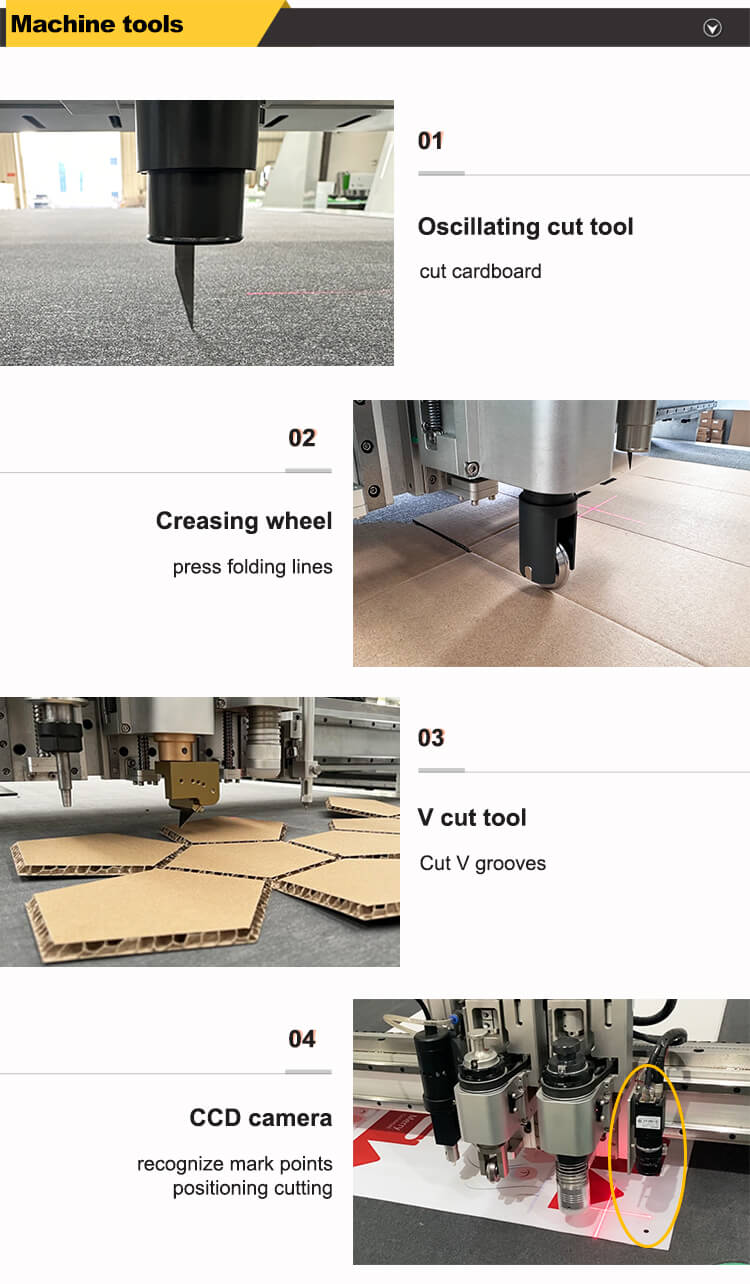

1. Clean, Fast, Automated Cutting

The high-frequency oscillating knife blade moves at thousands of strokes per minute, slicing cleanly through the fluted structure of PP hollow sheet without crushing or tearing the material. This ensures sharp, smooth edges every time, whether you are cutting intricate graphics for signs or straight lines for boxes. With cutting speeds up to 1500mm/s, you can process multiple sheets per hour, dramatically increasing your throughput compared to manual methods.

2. Perfect Folds and Rigid Corners

Creating a professional-looking box or display from PP hollow sheet depends on the quality of the fold. The SL1625HF is equipped with the essential tools for structural fabrication:

Creasing Wheel: Creates a precise, compressed channel along the fold line, allowing the material to bend cleanly without cracking or stressing.

V-Grooving Tool: Cuts a V-shaped channel, enabling the creation of sharp, rigid 90-degree corners for high-end boxes, displays, and structural components.

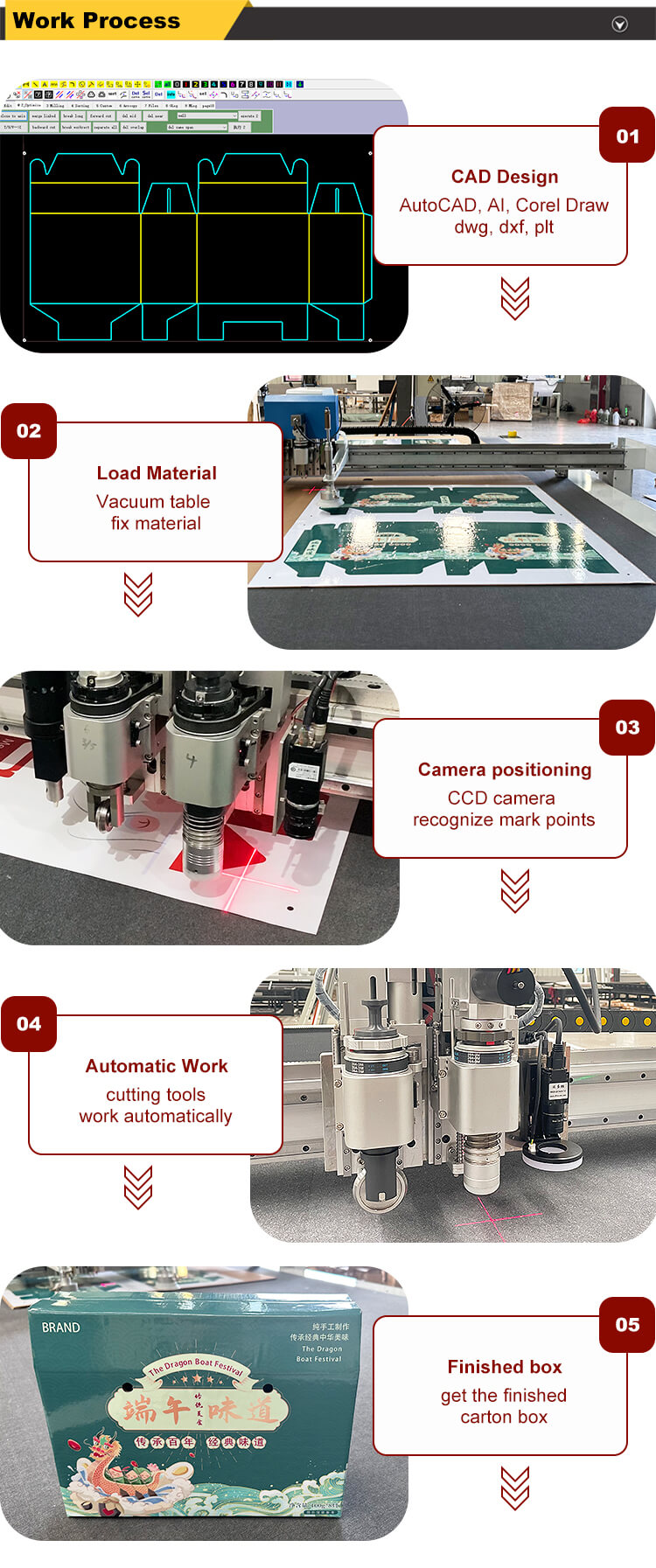

3. Large Format with Intelligent Nesting

The spacious 1600mm x 2500mm work table is perfectly sized to accommodate standard industrial sheets of PP hollow board, minimizing the need for pre-cutting. More importantly, the included intelligent nesting software automatically arranges your cut files to maximize material usage. It significantly reduces waste, saving you money on every job and boosting your profitability.

![cnc cardboard cutting machine cnc cardboard cutting machine]()

SL1625HF Technical Specifications

Parameter | Specification |

Model | SL1625HF |

Working Area | 1600mm × 2500mm (Customizable) |

Working Tools | Cutting Tool, Creasing Wheel, V-Grooving Tool |

Cutting Thickness | ≤40mm |

Cutting Tolerance | ±0.1mm |

Applicable Materials | PP Hollow (Coroplast), Honeycomb Board, Corrugated, Foam Board |

Applicable Markets | Advertising, Packaging, Industrial Fabrication, Printing |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Warranty | 3 Years |

The Go-To Solution for PP Hollow Sheet Applications

The SL1625HF is the ideal production tool for a wide range of industries that rely on PP hollow sheet.

Advertising & Signage: Effortlessly produce yard signs, real estate signs, A-frames, event signage, and complex point-of-purchase (POP) displays.

Reusable Packaging: Fabricate durable and lightweight custom totes, bins, and boxes for logistics, agriculture, and internal material handling.

Custom Partitions & Dividers: Create precise inserts and dividers for product packaging, protecting items during shipment and organizing contents within a case.

Industrial & Protective Solutions: Cut custom liners, floor protection sheets, and other protective components used in construction and manufacturing.

![cardboard box cutting machine cardboard box cutting machine]()

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our specialists have extensive knowledge of cutting plastic materials. We will help you configure the SL1625HF with the optimal blades and tools for your specific applications.

A Fully Integrated System: You receive a turnkey solution. The machine, software, and vacuum table are designed to work in perfect harmony, ensuring you are productive immediately.

Global Installation & On-Site Training: Our factory-certified technicians provide professional installation and comprehensive training for your team on machine operation, software use, and routine maintenance.

Authoritative 3-Year Warranty: We stand behind the robust engineering and premium components of our machines with an industry-leading 3-year warranty, guaranteeing the security of your investment.

Lifetime Technical Support: Your long-term productivity is our commitment. You gain a reliable partner with lifetime access to our expert support team for any operational or technical challenges.

Transform Your PP Hollow Sheet Production

Stop struggling with manual processes and start producing high-quality, professional products with speed and efficiency.

Contact us today to speak with a material specialist and request a quote and a free sample cut from your PP hollow sheet material.