Go from Design to Finished Box in Minutes: The SL1625CF Digital Cardboard Cutter

For businesses in packaging, printing, and product design, traditional die-cutting is a major barrier to agility. The high costs and long lead times for custom dies make short runs unprofitable, prototyping slow, and responding to client changes a logistical nightmare. You are forced into large inventory commitments and a slow, inflexible production cycle that stifles innovation.

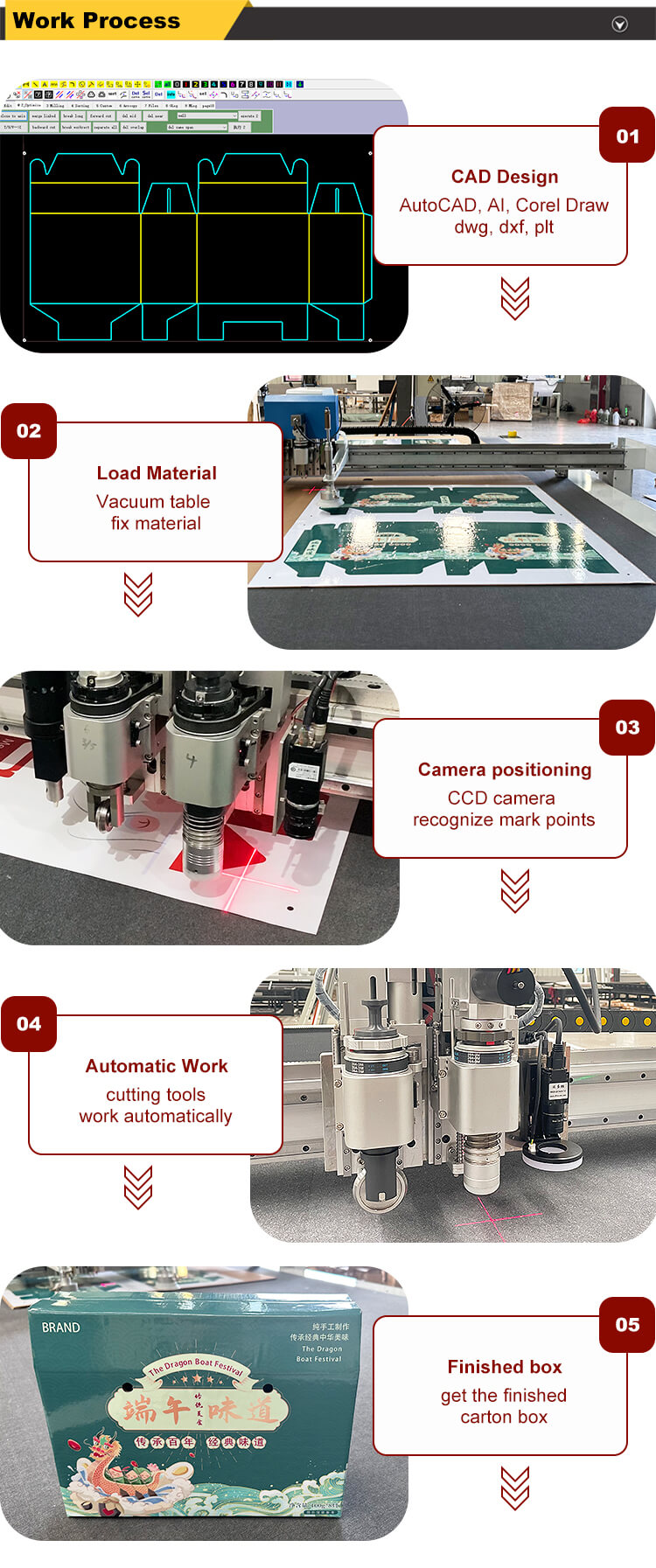

The SL1625CF CNC Cardboard Flatbed Digital Cutter is your all-in-one solution to break free. It integrates cutting, creasing, and V-grooving into a single, automated workflow, transforming your digital designs into perfectly finished boxes, displays, and inserts—on-demand, without the need for a single die.

Core Advantages: Built for Agile, On-Demand Production

The SL1625CF is more than a cutter; it's a complete packaging and prototyping workstation.

1. The All-in-One Toolset for Perfect Boxes

Produce a complete, ready-to-fold product in a single, automated operation. The multi-function tool head intelligently switches between three essential tools:

Oscillating Knife: Delivers clean, precise through-cuts on materials from corrugated board to rigid gray board without tearing or fraying.

Creasing Wheel: Creates crisp, uniform fold lines that ensure easy assembly and a professional finish, preventing the material from cracking.

V-Grooving Tool: Cuts precise V-shaped grooves at various angles (e.g., 45°, 60°, 90°), enabling the creation of sharp, rigid corners for high-end packaging and structural designs.

2. True On-Demand Flexibility: From 1 to 1,000

This is the end of die costs and minimum order quantities. The SL1625CF operates directly from your CAD files (AI, AutoCAD, CorelDRAW), allowing you to produce what you need, when you need it.

Zero Die Costs: Immediately eliminate tooling expenses and storage fees.

Rapid Prototyping: Create and test a new box design in minutes, not weeks.

Profitable Short Runs: Efficiently produce custom orders, seasonal packaging, and personalized items.

3. Intelligent and Efficient Workflow

Every component is engineered for maximum productivity and minimal waste. The regional adsorption vacuum table intelligently concentrates suction power only where your material is placed, ensuring a powerful hold-down for even small or warped sheets while saving significant energy. Paired with our included intelligent nesting software, the system automatically arranges your parts to maximize material yield, directly lowering your operational costs.

![cardboard box cutting machine cardboard box cutting machine]()

SL1625CF Technical Specifications

Parameter | Specification |

Model | SL1625CF |

Working Area | 1600mm × 2500mm (Customizable) |

Working Tools | Cutting Tool, Creasing Wheel, V-Grooving Tool |

Work Table | Vacuum Table (Regional Adsorption) |

Cutting Tolerance | ±0.1mm |

Applicable Materials | Corrugated Cardboard, Honeycomb Board, Gray Board, PP Hollow Sheet |

Applicable Markets | Packaging, Cushioning, Advertising, Crafts, Toys |

Drive System | Japan Servo Motor, Taiwan Guide Rail & Rack |

Software Suite | Machine Control Software, Intelligent Nesting Software |

Safety Device | Emergency Switches, Anti-Collision Device, Infrared Sensors |

Rated Power | 11KW |

Warranty | 3 Years |

The Ideal Solution for a Wide Range of Cardboard Applications

The versatility of the SL1625CF makes it an indispensable tool across multiple industries.

Custom Packaging & E-commerce: Produce custom-fit shipping boxes, product inserts, and void-fill solutions that reduce shipping costs and improve unboxing experiences.

Point-of-Sale (POS) Displays & Advertising: Create eye-catching freestanding displays, countertop signs, and promotional cutouts quickly and cost-effectively.

Prototyping & Sample Making: Allow design agencies and in-house R&D teams to rapidly iterate and present physical packaging samples to clients.

Crafts, Toys & Education: Fabricate intricate papercraft models, educational kits, and custom game components.

The SLCNC Partnership: Your Complete Fabrication Solution

We provide more than a machine; we deliver a comprehensive partnership built on expertise, authority, and trust.

Expert Consultation: Our team understands the intricacies of box design and material behavior. We will help you configure the perfect system, including the right tools and blades for your specific production needs.

A Fully Integrated System: You receive a turnkey solution. The machine, software, tools, and vacuum system are pre-configured to work together flawlessly, ensuring you are productive from day one.

Global Installation & On-Site Training: Our certified technicians provide professional installation and train your team on machine operation, software, and maintenance for a fast and successful implementation.

Authoritative 3-Year Warranty: We are so confident in the robust construction and reliability of our machines that we back the SL1625CF with an industry-leading 3-year warranty for your peace of mind.

Lifetime Technical Support: Your success is our mission. You gain a dedicated partner with lifetime access to our expert support team for any operational or application questions.

![gasket cutting machine manufacturer gasket cutting machine manufacturer]()

Ready to Revolutionize Your Packaging Production?

Stop letting die-cutting dictate your schedule and budget. Embrace the speed, flexibility, and quality of digital cutting to win more business and accelerate your innovation.

Contact us today to discuss your application with a cardboard cutting specialist and request a quote and a free sample cut.