Why Traditional Cutting Methods Are Costing You

In the competitive world of automotive upholstery, luxury fashion, and high-end furniture, every millimeter of material and every minute of production time counts. Are you still losing money to these outdated problems?

Your Current Pain Points | The Cost to Your Business | The Shilai Solution |

Material Waste | Inefficient manual nesting leads to up to 15% more material consumption. | Intelligent Nesting: Guaranteed material savings of 10-15% through AI-powered defect recognition. |

Inconsistent Quality | Manual cutting or laser methods result in uneven edges, scorching, or deformation. | Flawless CNC Blade Cut: Clean, smooth, non-scorched edges, preserving material value. |

Low Efficiency | Separate processes for cutting, punching, and marking slow down your entire production line. | All-in-One Workflow: Multi-tool head design completes all processes in a single pass. |

Data Loss & Errors | Physical patterns (paper/cardboard) are prone to damage, deformation, and manual error. | Digital Pattern Integrity: Cloud-based pattern database with one-click size modification. |

High Labor Costs | Reliance on skilled, expensive cutting technicians and high turnover. | Automated 24/7 Production: Reduces labor dependency and training time dramatically. |

![Leather & Upholstery Cutting Solutions Leather & Upholstery Cutting Solutions]()

The Shilai Advantage: Engineered for Your Success

At Shilai, we don't just sell machines; we engineer success for our partners. As a Chinese-leading brand in digital cutting technology, we have dedicated over 8 years to R&D, with 70% of our machines operating in the demanding, high-standard markets of Europe and North America. This is the Shilai difference: Experience, Expertise, Authoritativeness, and Trustworthiness built into every cut.

The Shilai Profit Equation: Precision + Yield = Unmatched ROI

Maximum Material Yield (The Profit Driver):

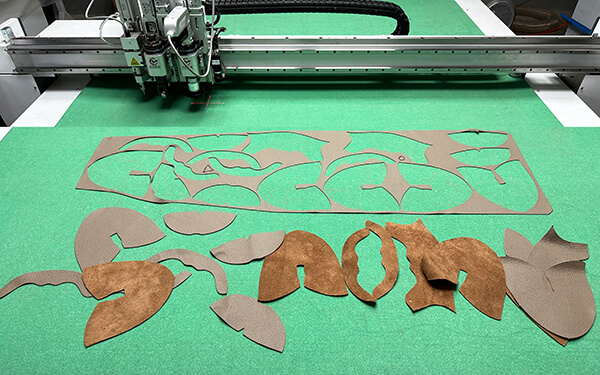

AI-Powered Hide Recognition: Our proprietary CCD Vision System scans the entire hide in seconds, automatically identifying the irregular outline and all defects (scratches, holes, scars) with pinpoint accuracy.

Guaranteed 10-15% Material Savings: The intelligent nesting software then calculates the absolute most efficient cutting path, prioritizing high-value parts and avoiding flaws. This direct material saving often pays for the machine within 1-2 years.

Flawless Precision & Quality (The Reputation Builder):

The Clean Cut Difference: Unlike laser cutting which burns and creates smoke/odor, our High-Frequency Oscillating Knife delivers a clean, mechanical cut. The result is a perfectly smooth, non-scorched edge that meets the stringent quality standards of the automotive and luxury fashion industries.

Digital Pattern Integrity: Say goodbye to paper templates. Digital patterns are stored in a secure database, ensuring they are never lost or deformed. Our one-click size modification feature allows for instant pattern recall and rapid adjustments, boosting design flexibility.

Streamlined, High-Speed Workflow (The Efficiency Booster):

True All-in-One Automation: Our multi-tool head design allows for cutting, V-grooving, punching, and automatic marking to be completed in a single, integrated process.

Continuous Flow Production: Features like automatic feeding/unloading and intelligent marking create a fully automated, assembly-line-style cutting process. This enables 24/7 continuous production with minimal human intervention, drastically reducing labor dependency and boosting overall throughput.

Technical Specifications & Capabilities: Built for Industrial Excellence

Feature | Detail | Impact on Your Production |

Cutting Technology | High-frequency Oscillating Knife (CNC Blade) | Zero Scorching/Odor: Preserves the quality and value of genuine leather. |

Material Recognition | Advanced CCD Vision System | Flawless Defect Avoidance: Maximizes material utilization by automatically mapping flaws. |

Nesting Software | Proprietary AI Auto-Nesting System | 15% Cost Reduction: Direct, measurable savings on every hide you process. |

Workflow Automation | Automatic Feeding/Unloading & Intelligent Marking | Reduced Labor: Enables one operator to manage multiple machines or focus on quality control. |

Tool Versatility | Multi-Tool Head Design (Cutting, Punching, Marking) | Process Consolidation: Eliminates bottlenecks and the need for separate machines. |

Pattern Management | Digital Database & One-Click Size Modification | Rapid Prototyping: Accelerates time-to-market for new designs and product lines. |

Applicable Materials | Genuine Leather, PU Leather, Fur, Artificial Leather, Microfiber Leather, Upholstery Fabrics. | Industry Versatility: Perfect for Automotive, Furniture (Sofa), Fashion (Bags/Apparel), and Footwear. |

Certification | CE Certified | Global Trust: Adherence to the highest international quality and safety standards for peace of mind. |

Frequently Asked Questions (FAQs)

Addressing the core concerns of procurement managers and production engineers:

Q1: How does Shilai's CNC blade cutting compare to laser cutting for leather?

A: Laser cutting uses heat, which can cause scorching, black edges, smoke, and a burnt odor, especially on genuine leather and PU. Our CNC oscillating blade technology uses a high-frequency mechanical cut, resulting in a perfectly clean, smooth, and odor-free edge, preserving the integrity and value of your material. This is the only method approved for high-end luxury goods.

Q2: What is "Intelligent Nesting" and how much material can I really save?

A: Intelligent Nesting is our AI-powered software that works with the CCD camera to scan the entire hide, map its irregular shape, and identify all defects. It then calculates the most efficient cutting path. Our clients typically report material savings of 10% to 15% compared to traditional manual or basic software nesting. For a company processing 100 hides a day, this translates to tens of thousands of dollars in annual savings.

Q3: We produce a wide range of products (e.g., sofas, car seats, bags). Can one machine handle all our needs?

A: Absolutely. Our multi-tool head design and digital pattern management system are built for versatility. The machine can handle various thicknesses and types of leather/upholstery, and the software allows for one-click size modification and instant recall of patterns for different product lines (sofas, apparel, footwear, bags). It's a future-proof investment for diversified production.

Q4: What about after-sales support and installation?

A: We offer seamless global support. This includes detailed installation videos, online learning platforms, a recommended spare parts list to minimize downtime, and 24/7 online support with a global network for on-site services. With 70% of our machines in Europe and North America, our support infrastructure is proven and reliable.

Ready to Maximize Your Yield and Precision?

Stop losing material and time to outdated cutting methods. Partner with Shilai to implement a cutting solution that guarantees precision, maximizes material yield, and drives down labor costs.

![Leather & Upholstery Cutting Solutions Leather & Upholstery Cutting Solutions]()

Explore Our Flagship Model:

CNC Leather Cutting Machine with Hide Recognition & Nesting

Take the Next Step: Request Your Free ROI Analysis

We understand that the right solution depends on your specific materials, production volume, and workflow. Don't guess your savings—know them.

Contact our experts today for a personalized consultation and a detailed ROI analysis based on your current material costs and production volume.