Waterjet vs. Laser vs. Oscillating Knife: Which Cutting Technology Is Right for Your Flexible Gaskets?

If you cut flexible gaskets—whether PTFE, graphite with foil, aramid fiber, rubber, foam, or PSA-backed laminates—you’ve likely faced this question: Which cutting method delivers the best balance of edge quality, accuracy, cleanliness, and cost?

The short answer? It depends on your materials and your critical quality requirements.

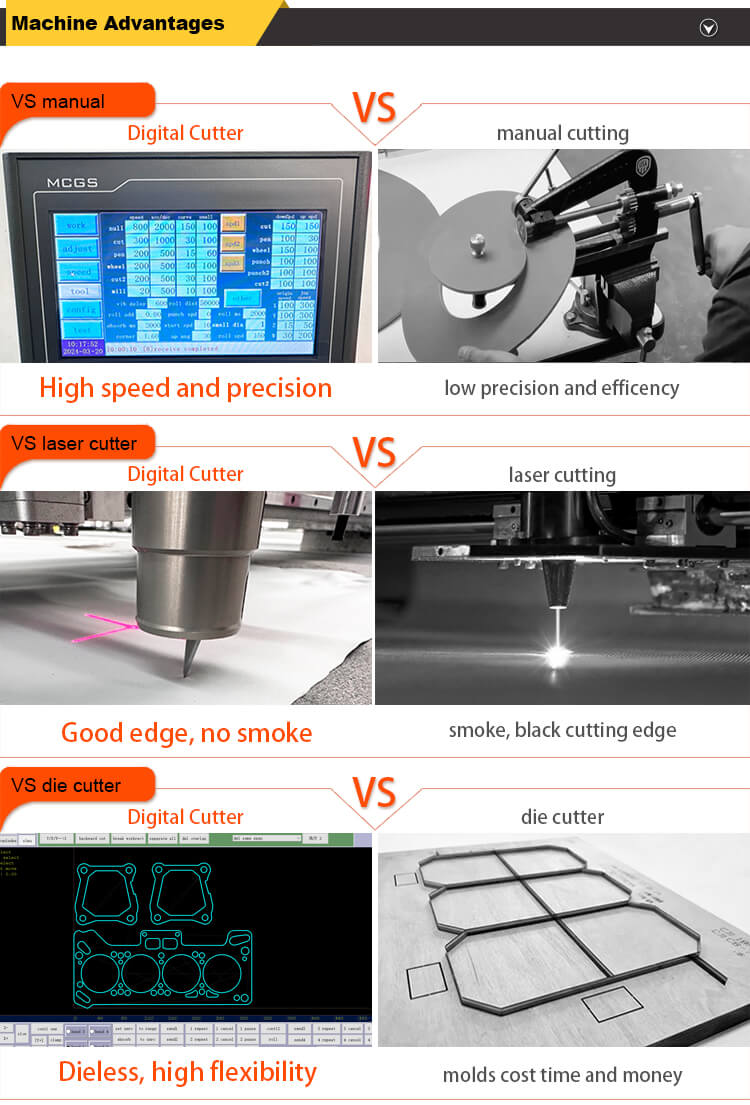

Waterjet, laser, and oscillating knife (digital CNC cutting) each have clear strengths—and real limitations—when applied to flexible gasket media. Choosing the wrong one can mean scrapped parts, inconsistent kiss-cuts, regulatory headaches, or unnecessary operating costs.

This guide cuts through the hype. We’ll compare how each technology actually performs on real gasket materials, where they shine, where they fall short, and how to pick the right one for your shop.

The Core Trade-Offs: Heat, Moisture, and Mechanical Shear

Before diving into specs, understand the fundamental physics:

Waterjet uses high-pressure water (often with abrasive) → wet process, no heat

Laser melts or vaporizes material → dry but hot, creates fumes

Oscillating knife mechanically shears the material → cold, dry, and clean

For flexible gaskets—especially those with adhesives, fillers, or layered constructions—these differences aren’t academic. They directly impact edge integrity, dimensional accuracy, and whether your parts even survive the cut.

How Each Technology Performs on Real Gasket Materials

Waterjet Cutting: Powerful, But Wet

Best for: Thick, dense, non-absorbent composites (e.g., solid rubber, some fiber-reinforced sheets)

Watch out for: Water-sensitive materials, small parts, and cleanup

Pros:

No heat-affected zone (HAZ)

Clean, burr-free edges on many elastomers

Handles very thick or hard materials well

Cons:

Water exposure ruins paper-backed, aramid, or PSA laminates (adhesive washes out, layers delaminate)

Kerf is wide (~0.8–1.2 mm), reducing yield

Taper on thick stock affects tolerance

Small parts can fall through slats or get lost in the catcher

Requires water treatment, sludge disposal, and wet-floor safety protocols

Practical note: If your shop already runs waterjet for metal or solid composites, it might work for simple rubber gaskets—but avoid it for anything layered, adhesive-backed, or absorbent.

Laser Cutting: Fast, But Fiery

Best for: Thin, heat-stable plastics without fillers or adhesives

Avoid for: Rubbers, foams, fluoropolymers, or anything with PSA

Pros:

Cons:

Heat causes charring, bubbling, or melting on most elastomers and organics

PSA adhesives boil, smoke, or re-solidify as sticky residue

Fumes from PTFE or filled rubbers require expensive filtration and may violate emissions regulations

Reality check: Laser can work beautifully on pure polyethylene or polyester films—but the moment you introduce rubber, foam, or adhesive, quality plummets unless you invest heavily in fume control and process tuning.

Oscillating Knife (Digital CNC): The Flexible Gasket Specialist

Best for: PTFE, graphite, aramid, rubber, foam, and especially PSA-backed laminates

Why it wins: Cold cutting, precise depth control, dry operation

Pros:

No heat, no moisture → ideal for sensitive materials

True kiss-cut capability with depth guardrails and per-zone calibration

±0.1–0.2 mm accuracy on stable sheets with proper mechanics

Excellent edge quality across the full material spectrum

Low operating cost: blades and underlay are cheap; no water or fume systems needed

Fast changeovers with digital recipes and barcode recall

Cons:

Not suited for metals or very hard composites

Requires good vacuum hold-down for thin or porous media

Bottom line: For shops focused on flexible industrial gaskets, the oscillating knife is the most versatile, reliable, and cost-effective choice—especially when kiss-cutting or tight tolerances are required.

Head-to-Head Comparison: Quick Decision Guide

Criteria | Waterjet | Laser | Oscillating Knife |

Edge quality on rubber/foam | Good (but wet) | Risk of charring/melting | Excellent, clean shear |

PTFE / filled PTFE | Possible, but slow & wet | Fumes, discoloration | Ideal—no heat, crisp edges |

Graphite / aramid sheets | Swelling/delam risk | Charring, hazardous fumes | Excellent with carbide blades |

PSA laminates (kiss-cut) | ❌ Not viable | ❌ Heat damages adhesive | ✅ Best-in-class |

Tolerance (stable sheets) | Good (watch taper) | Good on thin films | ±0.1–0.2 mm achievable |

Small IDs / bolt circles | Risk of part loss | Precise if no charring | Strong with kerf compensation |

Cleanliness & EHS | Wet, sludge, splash | Fumes, laser safety | Clean, low emissions |

Operating cost | High (water, abrasive, disposal) | Medium-high (filters, optics) | Low (blades, underlay) |

Material compatibility | Broad, but excludes wet-sensitive | Narrow for organics | Broadest for flexible gaskets |

Changeover speed | Moderate | Fast | Fastest (digital recipes) |

⚠️ Remember: Performance varies by material grade, thickness, and machine calibration. Always run sample cuts on your stock.

![automatic CNC gasket cutting machine (4) automatic CNC gasket cutting machine (4)]()

Material-Specific Tips: Getting the Best Results

PTFE & Filled PTFE

Waterjet: Works but slow; water can wick into skived layers.

Laser: Avoid—PTFE fumes are toxic, and edges discolor.

Oscillating knife: Use polished blades, low amplitude, and consider a two-pass cut for thick sections. Delivers clean, round IDs.

Graphite with Foil / Aramid Fiber

Waterjet: Risk of fiber swelling and abrasive contamination.

Laser: Produces conductive dust and char—requires HEPA filtration.

Oscillating knife: Carbide or coated blades with tuned oscillation prevent crumbling. Best dimensional control.

Rubber (NBR, EPDM, Viton) & Foams

Waterjet: Clean edges but wet parts; taper on thick sections.

Laser: Often melts or soots—especially on high-durometer rubbers.

Oscillating knife: Match blade geometry to durometer; use corner deceleration for sharp internal features.

PSA-Backed Laminates (Kiss-Cut)

Waterjet: Water compromises liner and adhesive.

Laser: Heat causes bubbling and inconsistent release.

Oscillating knife: The only reliable option—use depth guardrails, zone calibration, and validate with peel tests.

Accuracy, Speed, and Yield: Real-World Performance

Accuracy

Waterjet: Good, but taper on thick parts hurts repeatability.

Laser: Excellent on thin, stable films—but heat can warp organics.

Oscillating knife: Holds ±0.1–0.2 mm on PTFE/graphite with rigid frames and vision alignment.

Throughput

Waterjet: Slower on delicate or thin materials; better on thick composites.

Laser: Blazing fast on compatible films—but slows down when quality matters.

Oscillating knife: Optimized for HMLV (high-mix, low-volume); fast setup, smart pathing.

Yield & Scrap

Waterjet: Wider kerf + part loss through grates = lower yield.

Laser: HAZ scrap on heat-sensitive materials adds hidden cost.

Oscillating knife: Best nesting algorithms + clean edges = 5–12% higher material utilization.

Cost & Operations: What You’ll Really Pay

Factor | Waterjet | Laser | Oscillating Knife |

Capex | Medium–high (pump, catcher, tank) | Medium–high (enclosure, fume system) | Medium (scales with options) |

Opex | Water, garnet, pump maintenance, disposal | Optics, filters, assist gas, energy | Blades, underlay—minimal |

Facility Needs | Drain, water treatment, wet floor safety | Class-1 enclosure, fume abatement | Standard shop; dust extraction for graphite |

How to Choose: Match Technology to Your CTQs

Ask yourself:

✅ Do you cut PSA-backed laminates or require reliable kiss-cutting?

→ Oscillating knife is your only real option.

✅ Is your mix dominated by PTFE, graphite, or aramid fiber?

→ Oscillating knife delivers the best edge quality, accuracy, and cleanliness.

→ Only consider waterjet if you already manage wet processing and parts are large/simple.

✅ Are you cutting thin, unfilled plastic films (no adhesive)?

→ Laser can excel—fast, precise, small kerf—if you have robust fume control.

✅ Do you run thick, non-absorbent rubber or composite sheets?

→ Waterjet is viable—but validate taper and part retention.

✅ Is your shop HMLV with frequent engineering changes?

→ Oscillating knife wins: digital recipes, fast changeovers, traceability, and smart nesting.

Before You Buy: Your Vendor Evaluation Checklist

Don’t take specs at face value. Demand proof:

Sample cuts on your actual materials—with edge photos and dimensional reports

Kiss-cut peel tests across the entire bed (not just the center)

Small-ID roundness data and corner fidelity on tight radii

Cycle time per m²—not just “parts per hour”

Consumables cost breakdown: blades vs. optics vs. abrasive

EHS documentation: fume filtration specs, water disposal plans, safety certifications

Software demo: nesting efficiency, remnant reuse, recipe governance, ERP/MES integration

Final Recommendation

For the vast majority of flexible gasket manufacturers—especially those working with PTFE, graphite, aramid, rubber, foam, or PSA laminates—a modern oscillating-knife CNC system is the smartest, safest, and most cost-effective choice.

Laser has a narrow but valid role in thin, heat-stable film cutting—if you can manage fumes and compliance.

Waterjet remains useful for thick, non-absorbent composites—but it’s a poor fit for layered or adhesive-backed gaskets.

Pro tip: De-risk your decision with a side-by-side trial on your materials. Run A/B nesting tests. Do a 2–4 week pilot. Lock recipes by material and thickness. Track SPC on your CTQs from day one.

That’s how you avoid costly mistakes—and build a gasket operation that’s accurate, efficient, and scalable.